Railroad workers face daily risks of exposure to a wide range of toxic solvents through the maintenance, cleaning, degreasing, and repair of engines, cars, and rail equipment.

Tasks involving solvent-based degreasers, paints, adhesives, and fuels often lead to inhalation exposure or skin absorption.

Exposure can happen in enclosed spaces with poor ventilation, or outdoors where fumes from chemical solvents are present in the air. Many organic solvents (such as toluene, benzene, and methyl isobutyl ketone) pose serious risks to neurological and respiratory health, especially with repeated exposure.

In maintenance shops, rail yards, and engine repair areas, solvent mixtures found in cleaning agents and industrial fluids may include chlorinated hydrocarbons and other hazardous chemicals.

Railroad employees may be exposed while handling oily rags, using spray cleaners, or applying protective coatings to metal surfaces.

Chronic exposure to these substances is linked to toxic encephalopathy, liver damage, and increased cancer risks.

Even acute exposure to specific solvents like Stoddard solvent or methyl ethyl ketone can lead to confusion, headaches, and breathing problems.

Solvents are sometimes mistaken for common household cleaners, but the concentration and toxicity in industrial applications make them far more dangerous.

Workers are often unaware that their symptoms may be linked to long-term chemical exposure. Legal support is critical for victims suffering from illnesses caused by prolonged contact with these toxic chemicals.

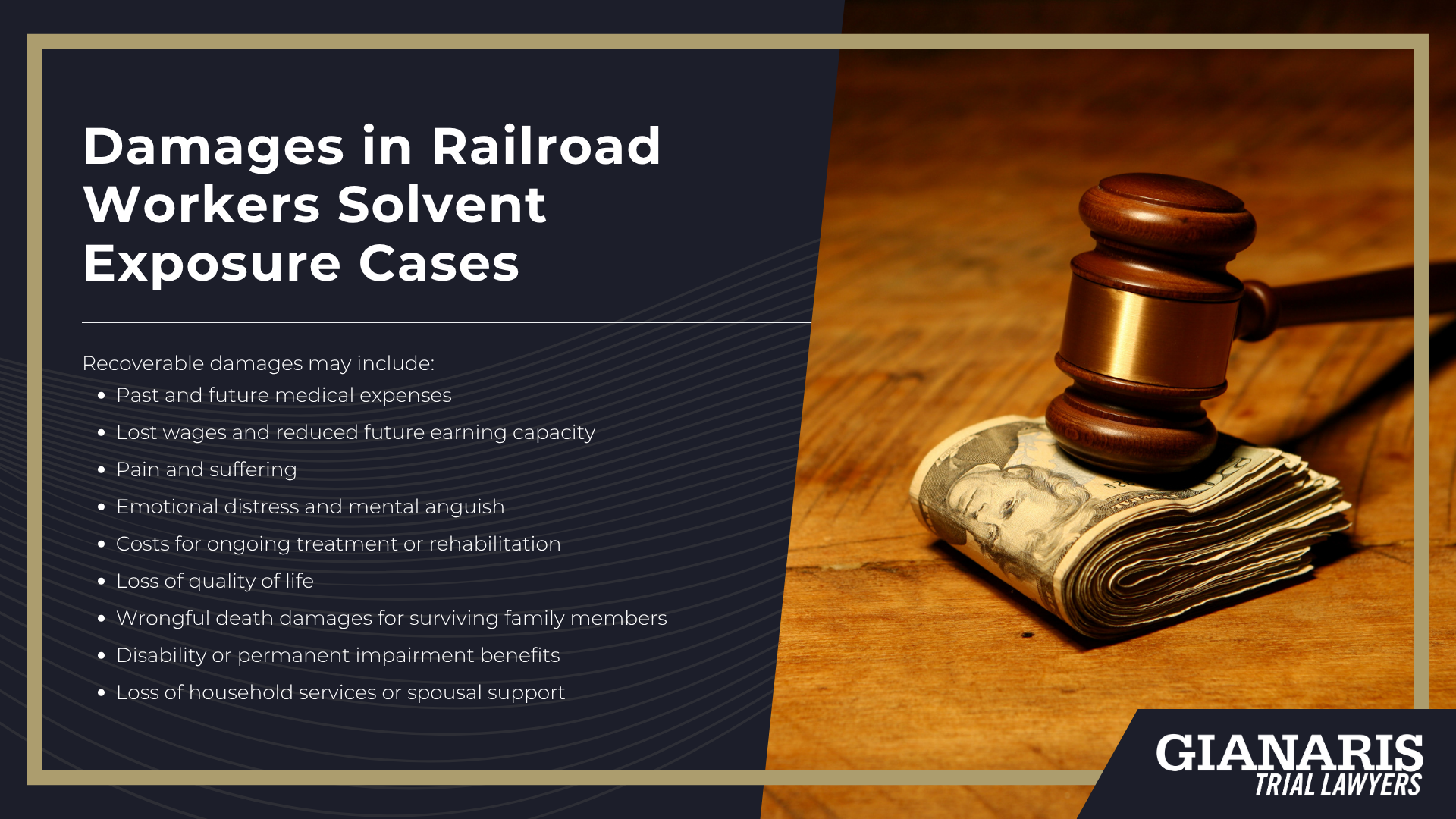

Common Routes of Solvent Exposure in the Railroad Industry Include:

- Inhalation of vapors from cleaning agents, degreasers, and paints

- Dermal absorption while handling solvent-soaked tools or materials

- Skin contact from spills or splashes during maintenance work

- Exposure to airborne particles in enclosed spaces without ventilation

- Use of solvent-based products like stoddard solvent and methyl isobutyl ketone

- Washing tools and parts with organic solvents

- Contact with contaminated clothing or personal protective equipment

- Cross-contamination in breakrooms, lockers, or shared workspaces

- Handling discarded rags and containers without proper disposal protocols

- Working with paints, fuels, adhesives, and coatings containing toxic chemical compounds

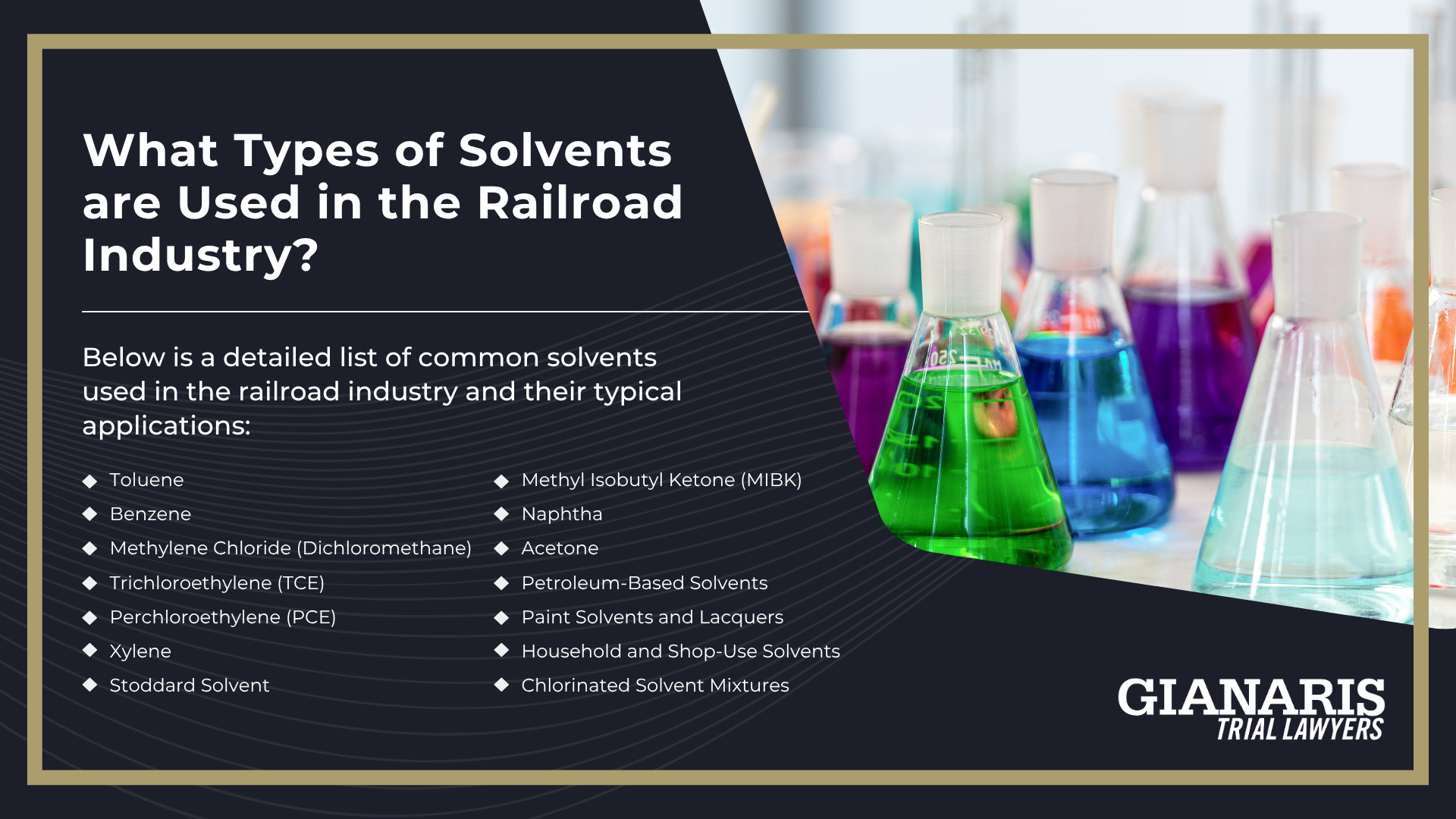

What Types of Solvents are Used in the Railroad Industry?

Railroad workers are frequently exposed to a wide array of chemical solvents during routine operations, maintenance work, locomotive cleaning, and component repair.

These solvents are used to degrease engine parts, strip paint, clean electrical systems, dissolve adhesives, and remove heavy grime from metal surfaces and machinery.

Many of these substances are volatile organic compounds (VOCs), and exposure may occur through inhalation, dermal contact, or residual contamination on work surfaces and equipment.

Prolonged or repeated exposure to these toxic substances (especially without adequate ventilation or protective gear) can result in severe health effects including neurological disorders, liver and kidney damage, various cancers, and toxic encephalopathy.

Chlorinated and petroleum-based solvents have been a particular concern in railroad shops, roundhouses, and maintenance yards across the United States.

Below is a detailed list of common solvents used in the railroad industry and their typical applications:

- Toluene – A widely used aromatic hydrocarbon found in degreasers, thinners, and adhesives. Chronic exposure can damage the central nervous system, cause fatigue, memory loss, and tremors.

- Benzene – Present in degreasing agents, adhesives, and fuels. A known carcinogen with strong links to leukemia, myelodysplastic syndrome (MDS), and other blood disorders.

- Methylene Chloride (Dichloromethane) – Found in paint removers and industrial cleaners. Causes respiratory irritation, is linked to liver toxicity and cancer, and may act as a central nervous system depressant.

- Trichloroethylene (TCE) – Once commonly used to degrease locomotive and brake parts. TCE is associated with kidney cancer, liver cancer, Parkinson’s disease, and immune dysfunction.

- Perchloroethylene (PCE) – Another chlorinated solvent used in cleaning and degreasing. Recognized by the EPA as likely carcinogenic; linked to neurological impairment and bladder cancer.

- Xylene – Found in cleaning solutions, varnishes, and thinners. Short-term effects include dizziness and nausea, while chronic exposure may cause liver damage and cognitive decline.

- Stoddard Solvent – A petroleum distillate used in degreasing and cleaning machinery. Prolonged inhalation exposure can cause CNS toxicity, skin irritation, and potential lung injury.

- Methyl Isobutyl Ketone (MIBK) – A solvent used in paints and coatings. May cause liver and kidney damage, and sensory irritation to eyes and airways.

- Naphtha – Used in cleaning agents and fuel blends. Highly flammable and toxic when inhaled; prolonged exposure may impair liver and kidney function.

- Acetone – Used to clean tools and strip paint or adhesives. Typically less toxic than others but still harmful in confined spaces or with frequent contact.

- Petroleum-Based Solvents – Found in fuels, degreasers, and hydraulic fluids. These include compounds like mineral spirits, diesel-range organics, and aliphatic hydrocarbons, all of which pose cumulative toxic risks over time.

- Paint Solvents and Lacquers – Frequently used in railroad car refurbishing and repainting. These mixtures often contain multiple VOCs, including toluene and MIBK, with combined neurotoxic and carcinogenic effects.

- Household and Shop-Use Solvents – Including cleaning agents like brake cleaner, contact cleaner, and general-purpose degreasers, often repurposed for industrial settings without proper hazard labeling.

- Chlorinated Solvent Mixtures – These mixtures often include compounds like TCE and PCE and are particularly hazardous due to their long-term environmental persistence and direct links to cancer, Parkinson’s disease, and reproductive harm.

Common Health Risks Linked to Toxic Solvent Exposure

Exposure to common solvents, including benzene exposure and toluene exposure, poses serious health hazards for workers in the railroad industry and beyond.

According to OSHA, toxic solvents are known to cause harm to the nervous system, reproductive organs, liver, kidney, and respiratory system.

Experimental animal studies also support that chronic exposure to organic solvents may lead to neurotoxic effects, including cognitive impairment, mood disorders, and sensorimotor neuropathy.

Long-term solvent exposure has been linked to high blood pressure, kidney damage, and increased cancer risk, including lung cancer and blood cancers associated with benzene exposure.

Workers exposed to paint solvents and chlorinated solvents may develop toxic encephalopathy, a form of chronic solvent-induced encephalopathy characterized by memory loss, depression, coordination problems, and behavioral decline.

Acute exposure to high solvent levels can result in headaches, dizziness, respiratory irritation, and chemical burns from skin contact or splashes.

Repeated exposure over many years is particularly dangerous and may contribute to neurological disorders, chronic bronchitis, and irreversible health complications. These conditions can severely hurt workers’ ability to continue working and dramatically reduce life expectancy.

Health conditions linked to toxic solvent exposure include:

- Chronic toxic encephalopathy and chronic solvent-induced encephalopathy

- Neurological disorders: memory impairment, tremors, mood changes, cognitive decline

- High blood pressure and cardiovascular strain

- Liver and kidney damage, including chronic kidney disease

- Cancer: lung cancer and blood cancers, especially from benzene

- Chronic bronchitis and respiratory irritation

- Chemical burns, skin irritation, and dermatitis

- Immune system impairment and reproductive harm

- Vision or hearing impairment associated with neurologic effects

These organic solvent exposures, common in railroad maintenance and cleaning tasks, may qualify as compensable occupational injuries under FELA when caused by employer negligence.