Railroad welders work at the intersection of intense heat, heavy equipment, and constant exposure to hazardous environments.

Their duties, whether performing rail welding on an active railroad track, repairing aging infrastructure, or installing components like rail anchors, consistently place them at risk of both immediate injuries and long-term health complications.

Modern processes such as gas pressure welding and enclosed arc welding may improve efficiency, but they still generate extreme temperatures, sparks, fumes, and physical strain that welders must manage every day.

Rail welding demands precision under circumstances that are rarely controlled.

Welders often operate in tight spaces, elevated track structures, or remote outdoor locations where weather, vibration from passing trains, and uneven terrain introduce additional hazards.

Even with improved welding methods, the job exposes workers to flying metal fragments, ultraviolet radiation, electrical currents, and intense sustained heat.

Beyond the physical stresses, railroad welders face continual exposure to toxic substances generated during cutting, grinding, and welding processes.

Fumes containing heavy metals, diesel particulates from nearby equipment, solvents used for cleaning, and dust from older ballast or infrastructure can accumulate over years of work.

As a result, welders must navigate the dual risk of sudden traumatic injuries and slow-developing occupational illnesses.

Unique risks that these professionals face include:

- Physical Injuries

- Chemical Exposure Injuries

Physical Injuries

Physical injuries among railroad welders occur because the job places workers in direct contact with extreme heat, electrical currents, heavy steel components, and fast-moving tools.

Processes like thermit welding, flash butt welding, and other intense fusion methods expose welders to molten iron, sparks, and weld metal that can reach temperatures high enough to cause instant burns.

Much of the work is performed on active or recently used railroad tracks, where vibrations, tight spaces, and harsh weather often make precision more difficult.

Over time, the combination of heat, repetitive motion, and physical strain can begin the early stages of chronic injury long before symptoms are recognized.

Employer negligence greatly increases these risks. When rail companies fail to maintain proper equipment, enforce safety protocols, or ensure adequate staffing, welders are forced to work in unsafe conditions.

Poor ventilation systems allow fumes and heat to build up, while a lack of protective barriers exposes crews to the sparks and high-temperature debris generated during the thermite reaction.

Inadequate training, especially for complex tasks like aligning rail segments or handling reactive materials, raises the likelihood of sudden accidents.

Long-term injuries often begin with minor strains, small burns, or repeated awkward movements, eventually developing into chronic pain, joint damage, or repetitive stress disorders.

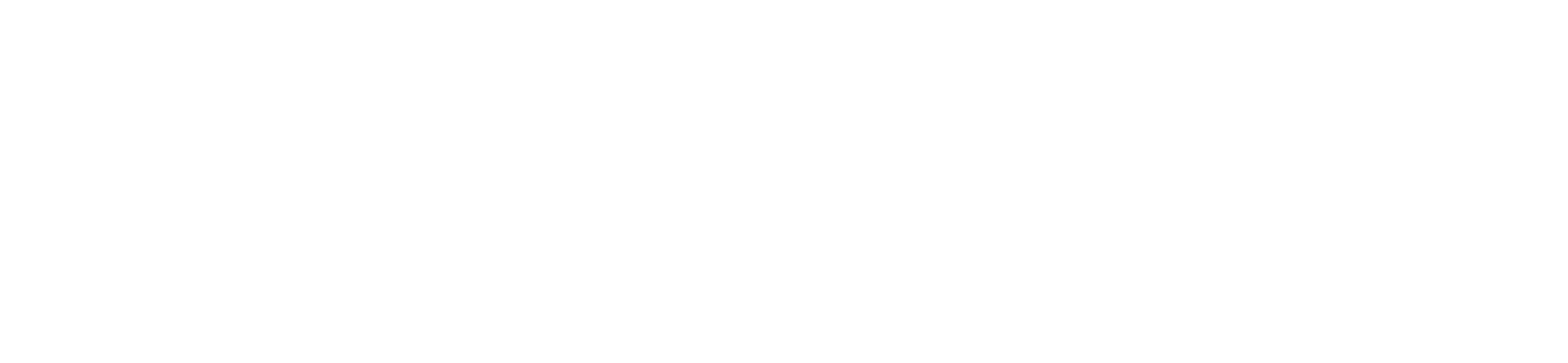

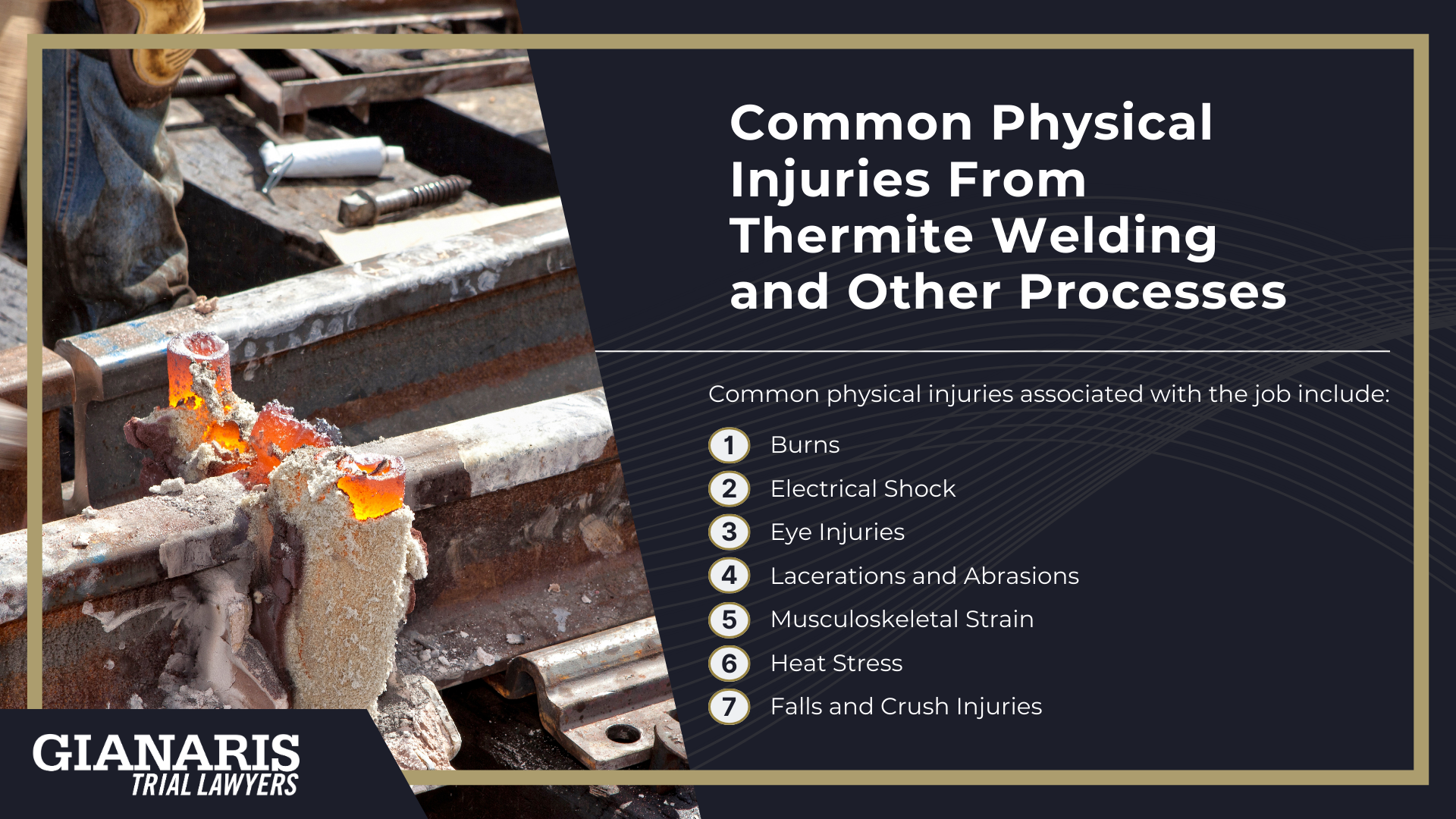

Common Physical Injuries From Thermite Welding and Other Processes

Thermite welding can cause physical injuries to workers.

Common physical injuries associated with the job include:

- Burns: Burns occur when welders come into contact with molten iron, weld metal, or heated tools. Thermite welding and cutting processes generate sparks and slag capable of causing severe skin damage.

- Electrical Shock: Exposure to high-voltage equipment used in arc welding and flash butt welding can result in shocks, falls, cardiac complications, or muscle injuries, especially when cables are worn or when worksites are wet.

- Eye Injuries: Ultraviolet radiation, metal fragments, and flying debris cause conditions like photokeratitis and corneal abrasions. Grinding, cutting, and rail preparation work increase this risk.

- Lacerations and Abrasions: Handling iron components, track parts, and sharp tools often leads to cuts and scrapes. These injuries are more likely when workers lack proper gloves or when equipment is poorly maintained.

- Musculoskeletal Strain: Lifting heavy track sections, operating grinders, and working in confined positions place continuous stress on the back, shoulders, and joints. These strains can develop into long-term mobility problems.

- Heat Stress: The combination of hot welding environments, outdoor temperatures, and insulated protective clothing exposes welders to exhaustion, dehydration, and heatstroke.

- Falls and Crush Injuries: Working on uneven rail beds, bridges, or in tunnels creates a high risk of slips, trips, and falling objects. Heavy steel components and tools can crush hands, feet, or other body parts if proper precautions are not taken.

Chemical Exposure Injuries

Chemical exposure injuries are some of the most serious and least visible risks faced by railroad welders.

Unlike burns or lacerations, these injuries develop slowly as welders inhale fumes, dust, and toxic particles created during rail welding and construction work.

Welding on aging railroad infrastructure often disturbs layers of rust, paint, ballast, and older materials that contain hazardous metals.

When welders cut, grind, heat, or fuse steel components, the process generates fumes that linger long after the molten metal enters a cooling phase.

These airborne toxins can accumulate in enclosed areas, tunnels, or low-ventilation worksites, increasing the likelihood of chronic inhalation.

Employer negligence amplifies these hazards significantly.

When companies fail to provide high-quality respirators, do not monitor air quality, or neglect proper ventilation systems, welders are left exposed to heavy-metal fumes and chemical byproducts at dangerous concentrations.

Various studies have linked occupational exposure to manganese, a common component in welding fumes, to neurological disorders resembling Parkinson’s disease.

This body of research demonstrates that repeated exposure can cause lasting damage to the central nervous system, affecting movement, memory, and cognitive function.

Failures to address contamination, inspect tools, or control dust further increase the chemical burden welders absorb throughout their careers.

Common chemical exposure injuries affecting railroad welders.

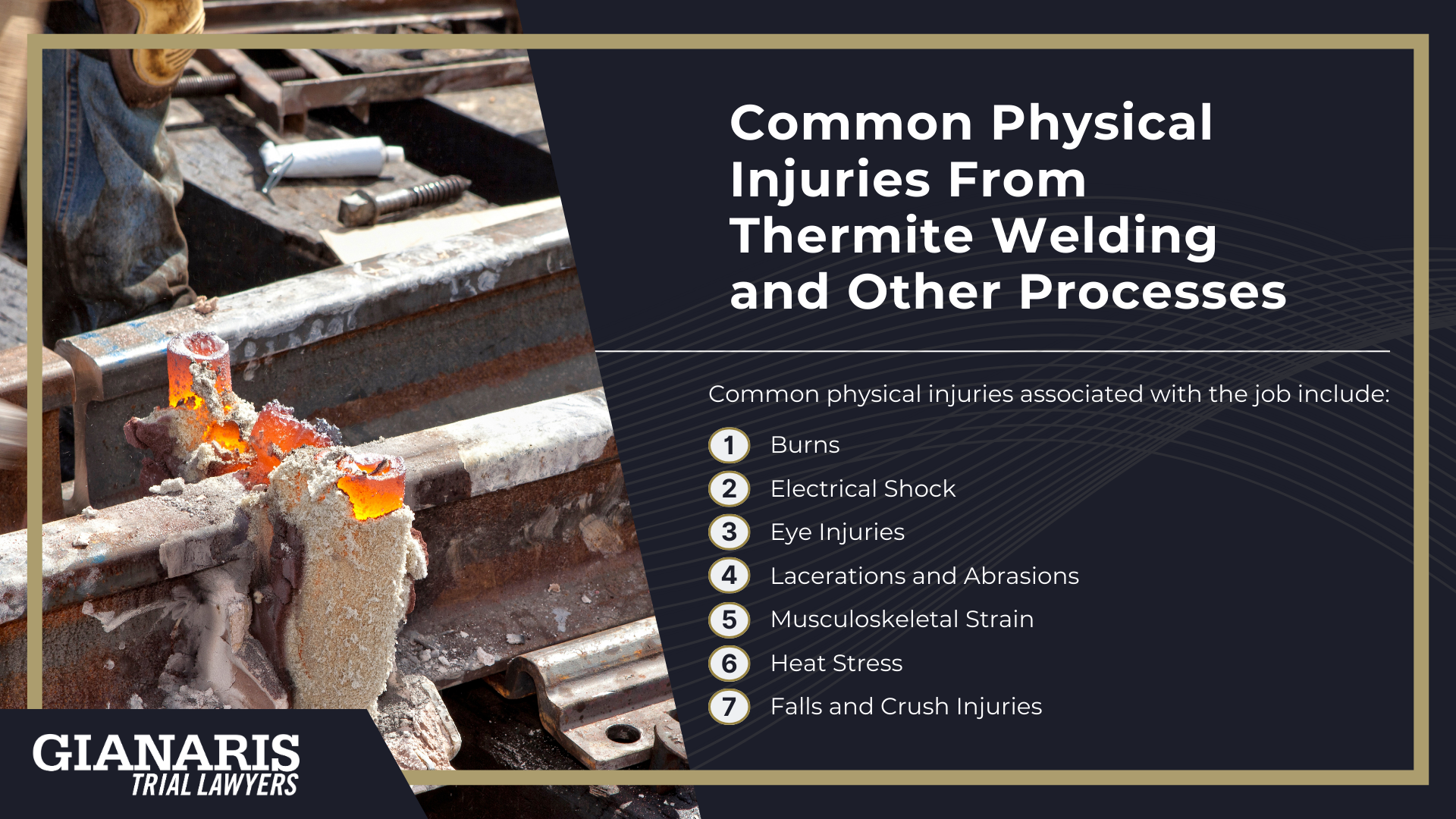

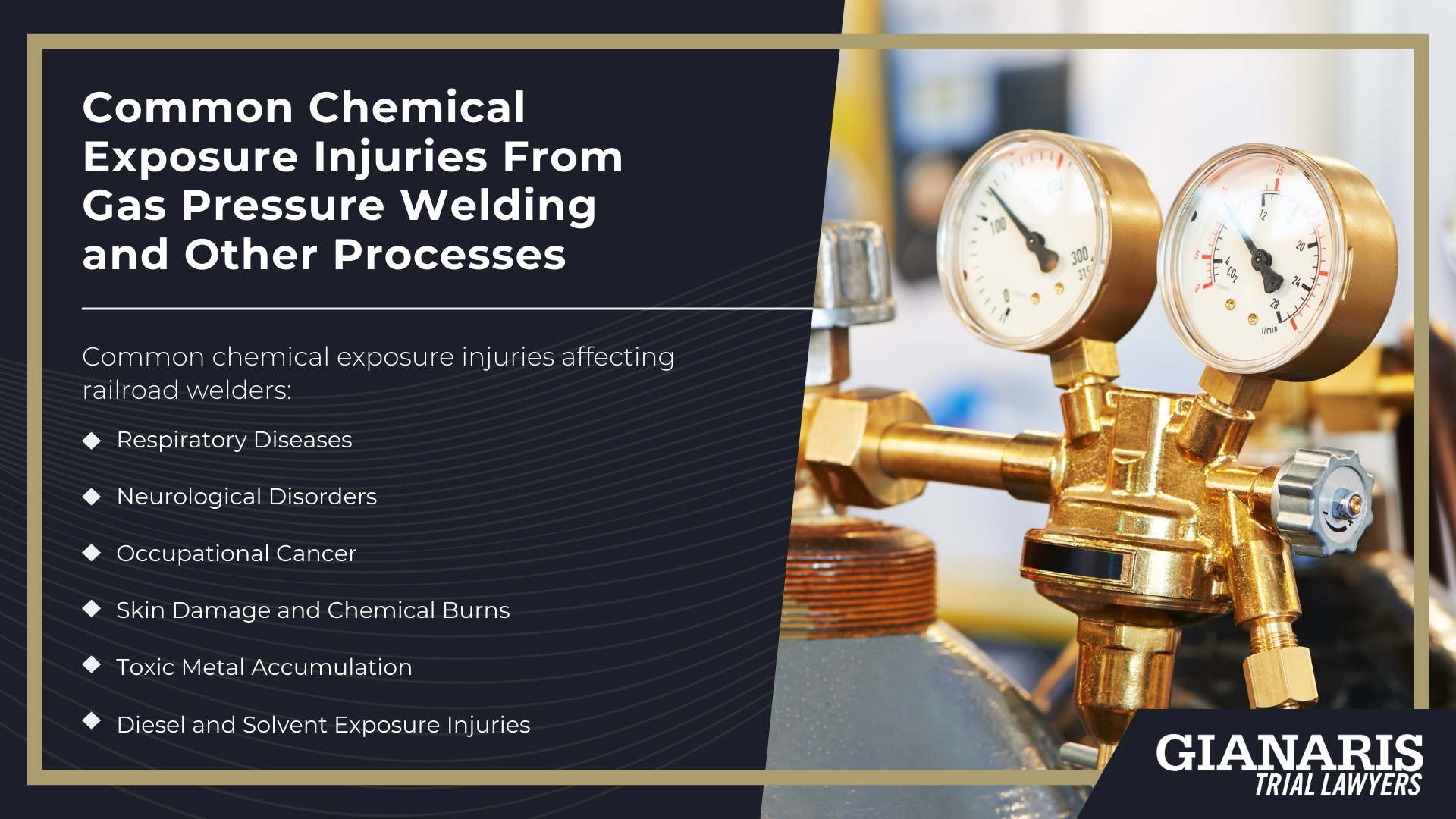

Common Chemical Exposure Injuries From Gas Pressure Welding and Other Processes

Gas-pressure welding and other hot-work processes can expose railroad welders to concentrated metal fumes, gases, and solvents, creating a predictable pattern of respiratory, neurological, and skin injuries that often develop over months or years of exposure.

Common chemical exposure injuries affecting railroad welders:

- Respiratory Diseases: Welding fumes contain chromium, nickel, manganese, and iron oxide particles that become airborne during high-heat processes. Inhalation can cause chronic bronchitis, reduced lung function, asthma-like symptoms, and long-term respiratory impairment.

- Neurological Disorders: Prolonged exposure to manganese and other neurotoxic metals can lead to cognitive decline, tremors, coordination problems, and symptoms resembling Parkinsonism. These effects may occur even when exposures are below outdated “acceptable” limits.

- Occupational Cancer: Hexavalent chromium, nickel compounds, and diesel exhaust are known carcinogens. Railroad welders who regularly work near engines, grinders, or torch operations face higher risks of lung, sinus, and bladder cancers.

- Skin Damage and Chemical Burns: Contact with solvents, degreasers, and metal-cleaning agents can cause dermatitis, rashes, and delayed chemical burns. Contaminants trapped in gloves or clothing can intensify skin irritation.

- Toxic Metal Accumulation: Chronic inhalation of iron oxide, rust, silica dust, and other particles can lead to siderosis (“welder’s lung”) and long-term lung scarring. Exposure increases in older facilities where electric tools disturb deteriorating materials.

- Diesel and Solvent Exposure Injuries: Working near idling locomotives or fuel-powered grinders exposes welders to benzene, formaldehyde, and hydrocarbons that can damage the liver, kidneys, and cardiovascular system.