As a railroad trackman, your main job is to keep the track structure safe enough for trains to move without derailment.

Every part of the rail line, including rails, ties, ballast, switches, crossings, joints, and right-of-way surfaces, depends on the work you and your crew perform day after day.

Track can shift, settle, crack, or deform with heat, cold, vibration, and train load.

Your job is to find those problems, fix them, and prevent new ones from forming.

Core Daily Responsibilities

As a trackman, your day centers on inspection, repair, and prevention: hands-on work that keeps track geometry within spec and trains moving safely.

Your work usually includes:

- Inspecting the track for broken ties, cracked rail, loose fasteners, or wide gauge

- Replacing ties that are damaged, rotten, or loose

- Lifting and lining the track to correct alignment and surface

- Tamping ballast so the track structure stays supported

- Maintaining switches and frogs, which need constant attention

- Cutting or grinding the rail when sections must be repaired

- Clearing vegetation and applying weed-control chemicals along the right-of-way

As in other railway-related roles, these tasks are repetitive, physically demanding, and time-sensitive.

You’re expected to find problems before they become derailment risks.

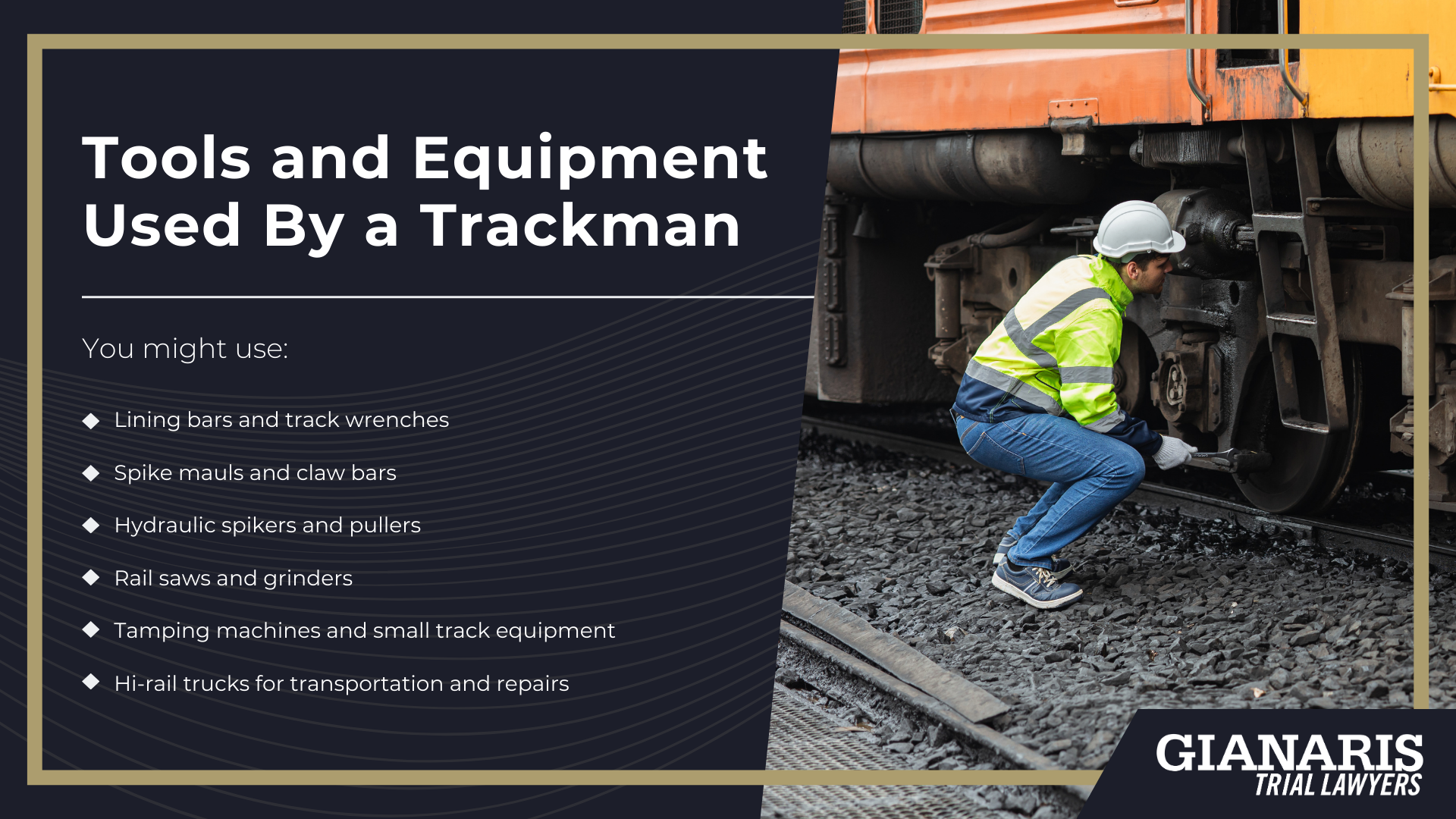

Tools and Equipment Used By a Trackman

Track work relies on a mix of hand tools and small machines.

You might use:

- Lining bars and track wrenches

- Spike mauls and claw bars

- Hydraulic spikers and pullers

- Rail saws and grinders

- Tamping machines and small track equipment

- Hi-rail trucks for transportation and repairs

Each tool has its own hazards: impact, vibration, weight, pinch points, and noise.

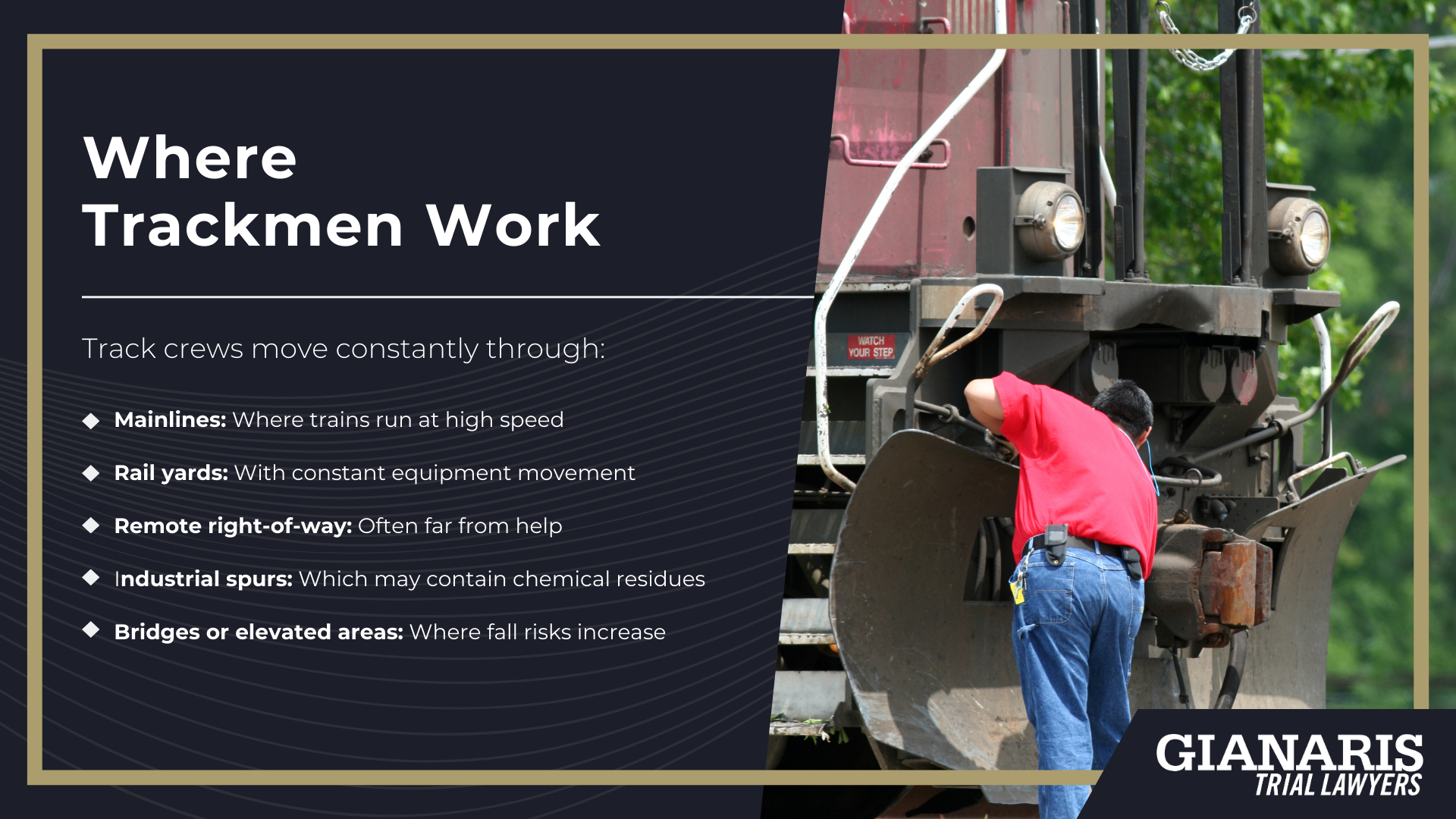

Where Trackmen Work

Unlike other railroad personnel (like brakemen), you rarely work in one place for long.

Track crews move constantly through:

- Mainlines: Where trains run at high speed

- Rail yards: With constant equipment movement

- Remote right-of-way: Often far from help

- Industrial spurs: Which may contain chemical residues

- Bridges or elevated areas: Where fall risks increase

Every location changes the type of risk you face.

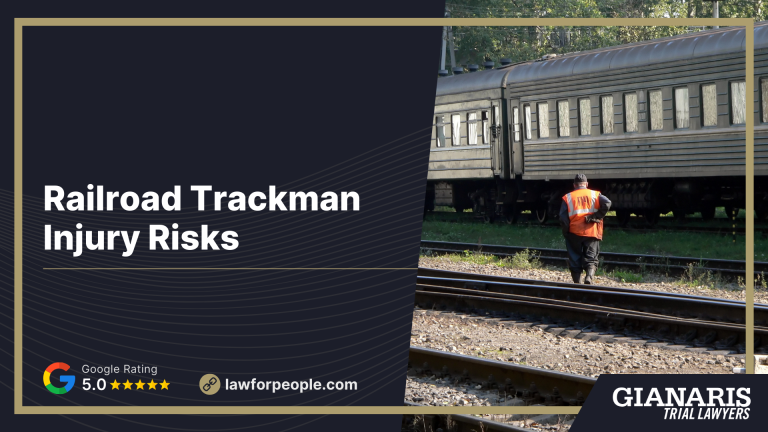

Why the Job Is Hazardous

Despite safety rules and better equipment, track maintenance remains high-risk work with daily exposures that can injure you quickly or wear you down over time.

Even with modern rules, track work still exposes you to:

- Heavy lifting

- Repetitive strain

- Noise and vibration

- Extreme heat and cold

- Tight deadlines and production pressure

- Long-term contact with creosote, diesel fumes, solvents, herbicides, and other chemicals

These conditions explain why so many trackman injuries and long-term health issues develop over time.