Physical injuries happen fast when you’re a railroad equipment operator.

After all, you work around machines powerful enough to lift rail, crush ballast, and move thousands of pounds of material in seconds.

You also share your work environment with railroad brakemen, railroad conductors, shopmen, and shop and car employees, all of whom rely on you to keep the job site safe and coordinated.

When something goes wrong, every person in the area can be placed at risk.

Heavy Equipment Accidents

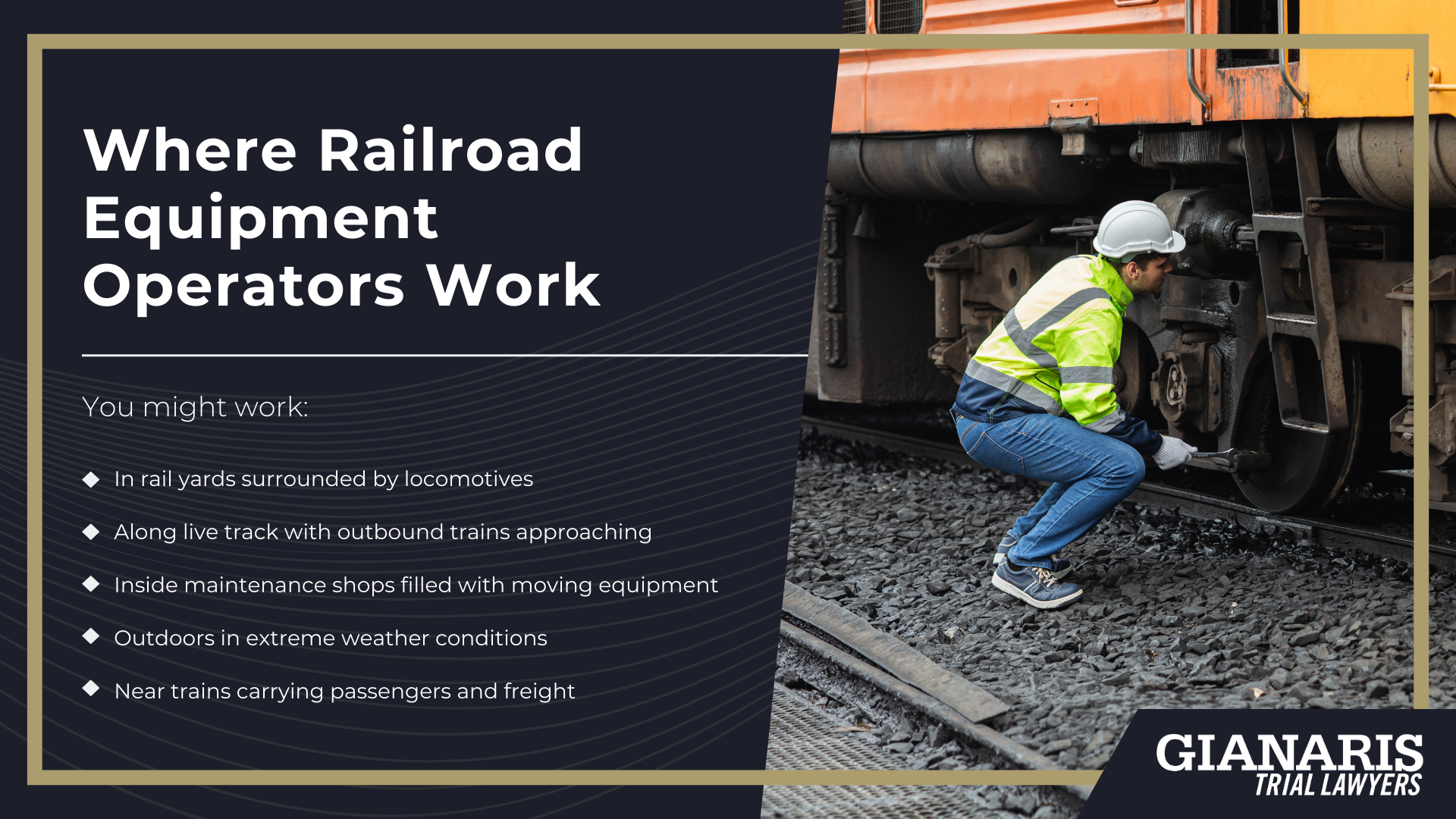

You operate heavy equipment in tight spaces where trains, locomotives, and train cars move constantly.

Accidents often occur when:

- Equipment swings unexpectedly

- Operators lose visibility

- A railroad employer allows unsafe spacing between machines

- Outbound trains move through an active zone

- Brakes or safety systems fail

These accidents cause crushing injuries, broken bones, or life-changing trauma.

Injured railroad employees often require long-term medical treatment and face lost earnings that create immediate financial stress.

Pinch and Crush Injuries

Rail yards and track zones leave very little room for error.

Operators, brakemen, and conductors often work within inches of moving equipment.

Crush injuries happen when:

- Rail or ties shift unexpectedly

- Machines pin workers against cars or structures

- Equipment malfunctions

- Communication breaks down between departments

These are some of the most serious injuries in the railroad industry and often become the center of a future FELA claim.

Overexertion and Musculoskeletal Strain

Many operators still handle heavy tools, hoses, rail components, and mechanical attachments by hand.

Overexertion is common because the job requires:

- Lifting in awkward positions

- Pulling or pushing attachments

- Securing equipment in unstable ballast

- Repeated climbing in and out of machines

- Long hours spent working outdoors in extreme weather conditions

These injuries build up slowly.

They often show up in medical records as chronic back pain, shoulder injuries, or knee damage.

Shopmen and car department employees experience similar long-term strain.

Repetitive Motion Disorders

Railroad work requires the same motions day after day.

Injuries develop in the hands, elbows, wrists, and shoulders.

These conditions are often linked to:

- Constant vibration

- Handling rail components

- Operating controls for long periods

- Tension from stabilizing yourself on uneven ground

Many injured workers do not realize these are covered under the Federal Employers’ Liability Act because the damage develops gradually.

Whole-Body Vibration Injuries

Operating tampers, regulators, skid steers, and excavators exposes your body to intense vibration.

Whole-body vibration can cause:

- Spinal compression

- Nerve damage

- Lasting back injuries

- Joint deterioration

Railroad brakemen, conductors, and shop and car department employees often report similar problems when they ride equipment or stand near running locomotives.

Hand-Arm Vibration Syndrome

Hand–Arm Vibration Syndrome (HAVS) is a progressive, work-related condition caused by long-term exposure to vibrating hand tools, machine controls, and on-track equipment.

Prolonged exposure to vibrating tools and machine controls can lead to:

- Numbness

- Reduced grip strength

- Pain in the hands and forearms

- Long-term nerve damage

This condition affects your ability to operate equipment, secure tools, and perform essential job duties.

Slip, Trip, and Fall Hazards

Rail yards and track zones are filled with hazards that can cause slip, trip, and fall hazards.

Hazards can include:

- Unstable ballast

- Uneven ground

- Leaking fluids

- Debris from maintenance work

- Ice and mud

Falls frequently injure the same types of workers who share your environment.

Brakemen, conductors, and shop and car employees are often injured in the same locations because they move between cars and equipment throughout the day.

Hearing Loss

Railroad equipment operators face some of the highest noise levels in the railroad industry.

Constant exposure to the following causes permanent hearing loss when the railroad employer fails to provide proper hearing protection.

Factors that could cause hearing loss include:

- Engines

- Grinders

- Tampers

- Regulators

- Passing trains

- Impact tools

Equipment Rollovers

Skid steers, excavators, and tampers can tip or slide on ballast or loose ground.

Rollovers often happen when:

- Equipment is positioned on a slope.

- Ground conditions are unstable.

- Visibility is low.

- The employer fails to mark hazards or level the work area.

Rollover injuries are severe and can require surgery, long-term rehabilitation, or the end of a railroad career.

Line-of-Fire Hazards

Every worker on the job site is at risk when equipment swings, loads shift, or tools break under pressure.

Line-of-fire injuries affect operators as well as other railroad workers.

Those who could be effected include:

- Railroad brakemen

- Railroad conductors

- Shopmen

- Locomotive engineers

- Shop and car employees

If the employer fails to enforce safety procedures or provide proper training, a line-of-fire injury becomes strong evidence in a future legal claim.

Fatigue-Related Injuries

Railroad work often includes long hours and demanding schedules that reduce alertness.

Fatigue increases the risk of injury for everyone on the job, especially in busy rail yards or active track zones.

Extended shifts, night work, and irregular call-outs can disrupt circadian rhythms and slow reaction times around moving equipment.

Microsleeps and delayed decision-making turn routine tasks into high-consequence events, increasing the likelihood of mistakes, near misses, and serious injuries.

Weather-Related Hazards

On the railroad, the weather could create hazards.

Operators frequently work outdoors in:

- Extreme heat

- Snow

- Rain

- Freezing temperatures

- High winds

Weather affects visibility, machine stability, and the physical condition of every worker on site.

When the employer fails to adjust staffing or procedures, injuries become more likely.