The work performed by brakemen is physically demanding, high-risk, and essential to the operation of freight and passenger rail systems across the country.

Brakemen operate in close coordination with engineers, switch operators, and yard crews to ensure safe railcar movement, coupling, and braking: all tasks that involve constant exposure to moving equipment and unpredictable environments.

These responsibilities place brakemen in harm’s way more often than most roles in the industry, and the consequences of a single accident can be life-altering.

At Gianaris Trial Lawyers, we place special focus on representing the unique challenges brakemen face, because we understand the nature of the job and what’s at stake when things go wrong.

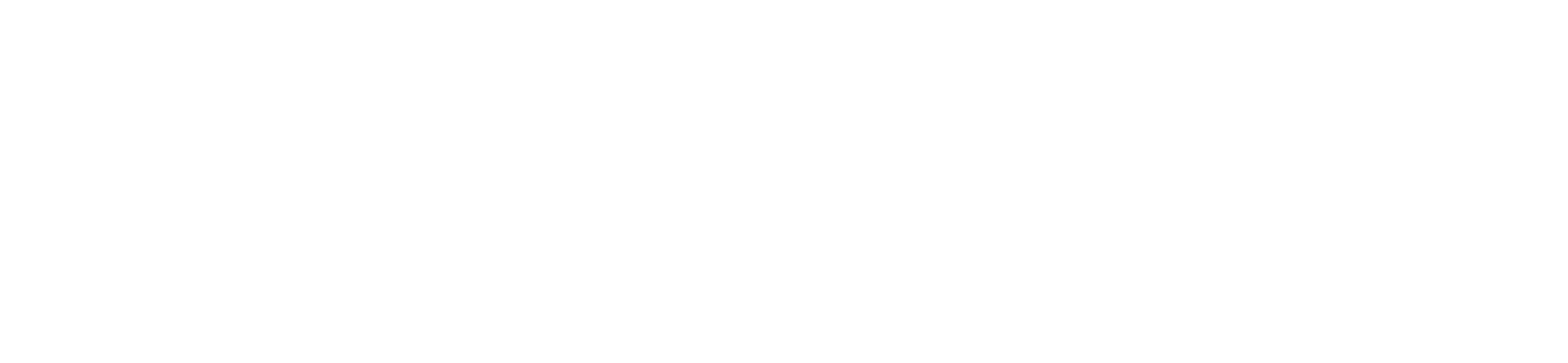

A significant number of FELA claims involve brakemen who suffered preventable harm while doing the very work that keeps the rail system running.

Whether you’re an injured railroader recovering from trauma or a family pursuing justice after a wrongful death, our team is equipped to build a case grounded in the reality of what brakemen endure.

Every detail of the role matters (from weather conditions to lack of safety protocols) and we use that knowledge to strengthen your claim.

In the next sections, we’ll break down the primary categories of risk brakemen face on the job.

Physical Injury Risks for Railroad Brakemen

Railroad work performed by brakemen often involves fast-moving equipment, uneven terrain, and physically strenuous tasks, all of which create a high risk of injury.

Despite evolving safety standards, gaps in training, outdated practices, or lack of proper enforcement can result in serious, preventable harm.

Over the course of many years in the field, even minor injuries can develop into chronic health conditions that limit a worker’s ability to earn a living.

Brakemen face both sudden trauma and cumulative physical stress from repeated exposure to dangerous conditions.

Common physical injuries among railroad brakemen include:

- Crush injuries from coupling or decoupling railcars

- Fractures and broken bones from slips, trips, and falls

- Traumatic brain injuries from falls or being struck by equipment

- Back and spinal injuries from heavy lifting or awkward movement

- Shoulder and knee damage from jumping on or off railcars

- Amputations or severe lacerations from mechanical failures

- Burns and electrocution from malfunctioning equipment

- Hearing loss from prolonged exposure to loud rail environments

- Repetitive stress injuries affecting joints, muscles, and connective tissue

- Soft tissue injuries and sprains from sudden impacts

- Internal injuries from derailments or sudden stops

- Vision damage due to debris or chemical exposure during mechanical tasks

Chemical Exposure Risks for Railroad Brakemen

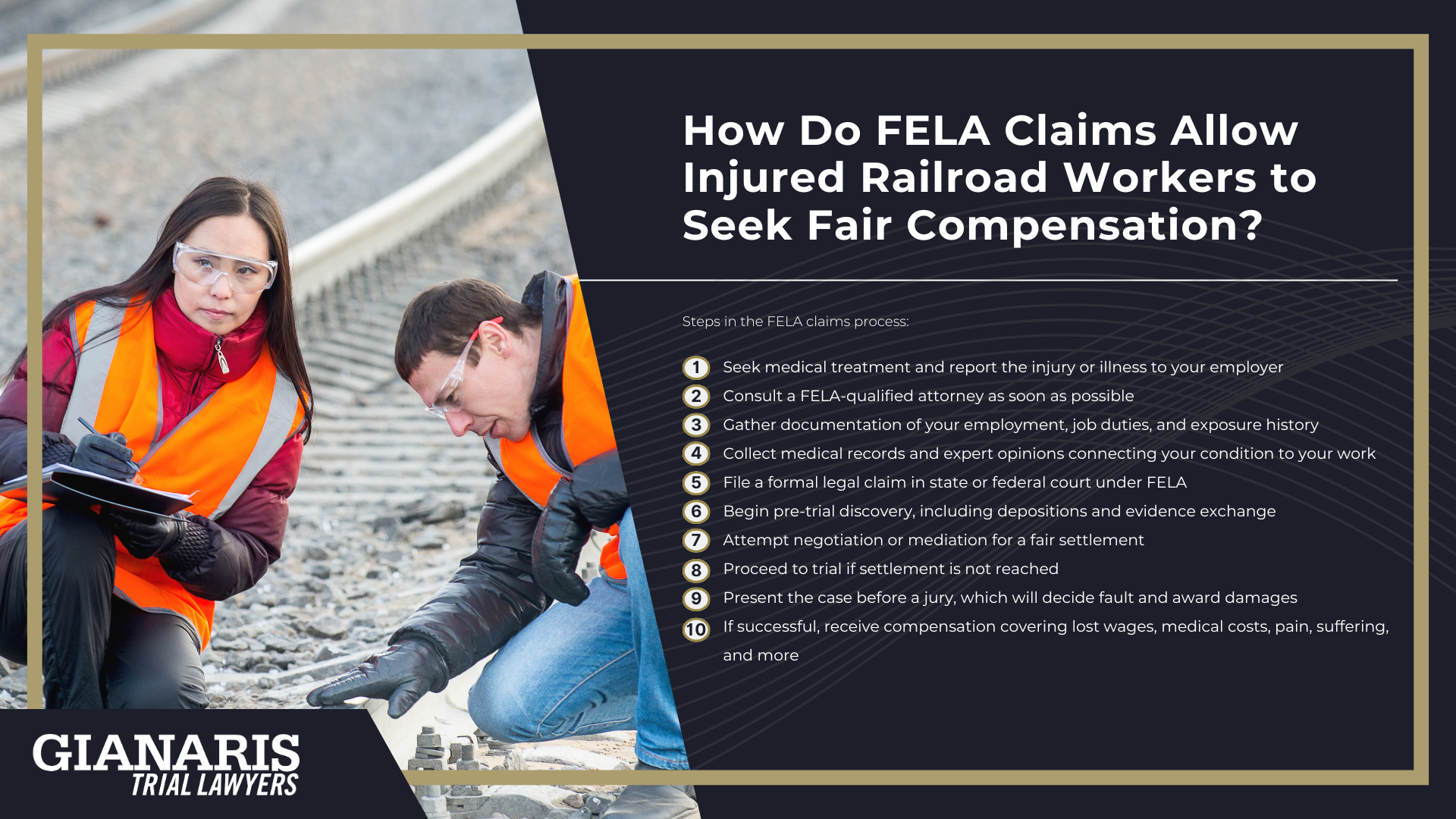

In addition to the risk of traumatic injury, brakemen face serious long-term health threats due to routine exposure to toxic substances throughout their employment.

These exposures often occur through inhalation, skin contact, or contaminated equipment, especially during tasks involving fuel systems, brake components, or cleaning agents.

When a negligent railroad employer fails to provide protective equipment or warn workers about known hazards, brakemen may suffer lasting harm without even realizing the cause until years later.

Chemical exposure injuries can be devastating and often appear only after prolonged periods of work in unsafe environments.

Common chemical exposure risks for brakemen include:

- Diesel exhaust inhalation while working near idling locomotives

- Benzene exposure from solvents, degreasers, and diesel fuel

- Asbestos exposure from older brake pads and insulation materials

- Silica dust inhalation during ballast work or yard maintenance

- Chemical burns from cleaning agents used on railcars and equipment

- Inhalation of welding fumes during on-site repairs or modifications

- Contact with creosote-treated railroad ties during yard operations

- Herbicide and pesticide exposure during vegetation control work

- Heavy metal exposure (e.g., lead, cadmium) from paint, coatings, or components

- Repeated contact with petroleum-based lubricants and hydraulic fluids

- Residual contamination from fuel spills or leaks in poorly ventilated areas