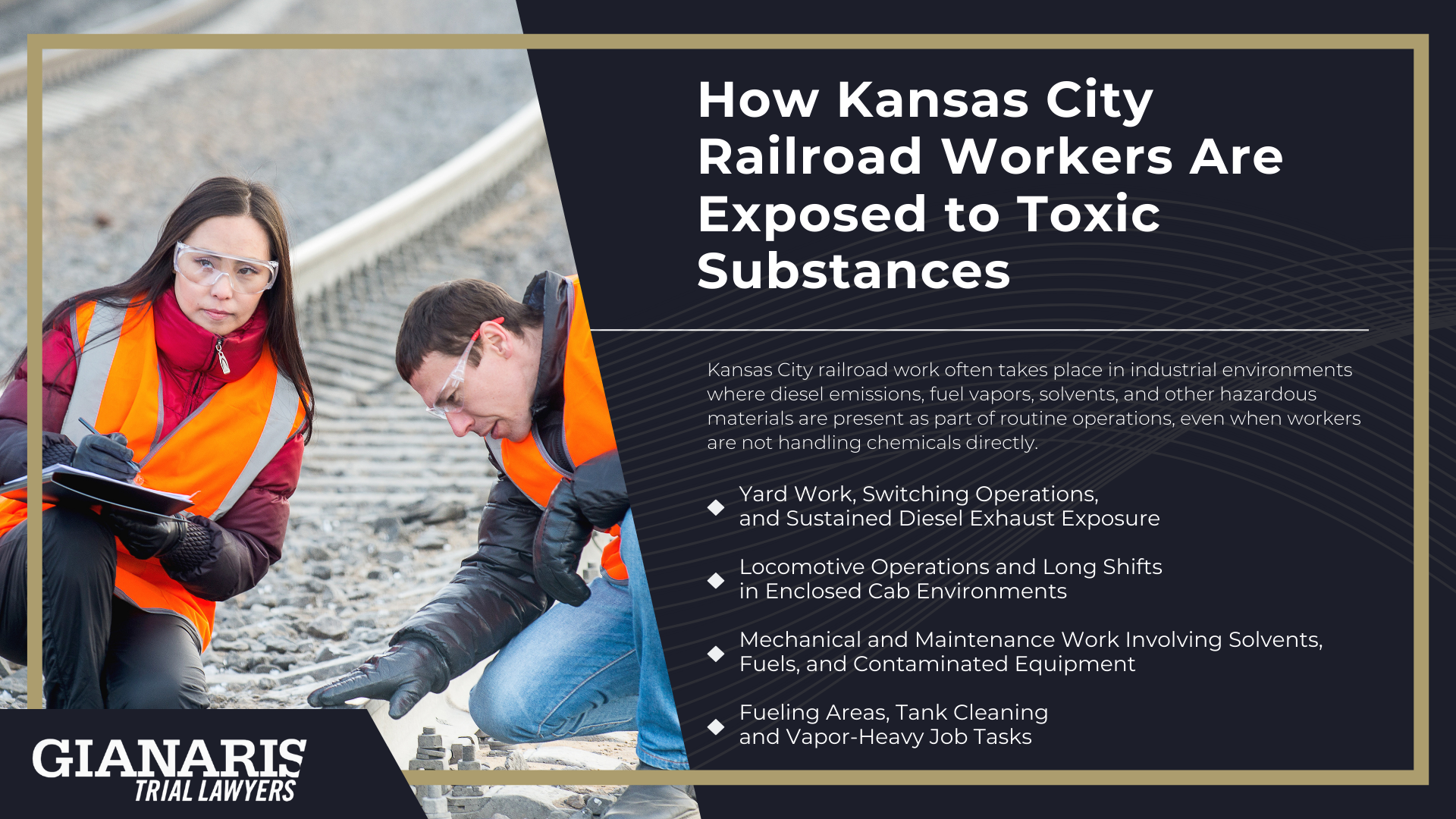

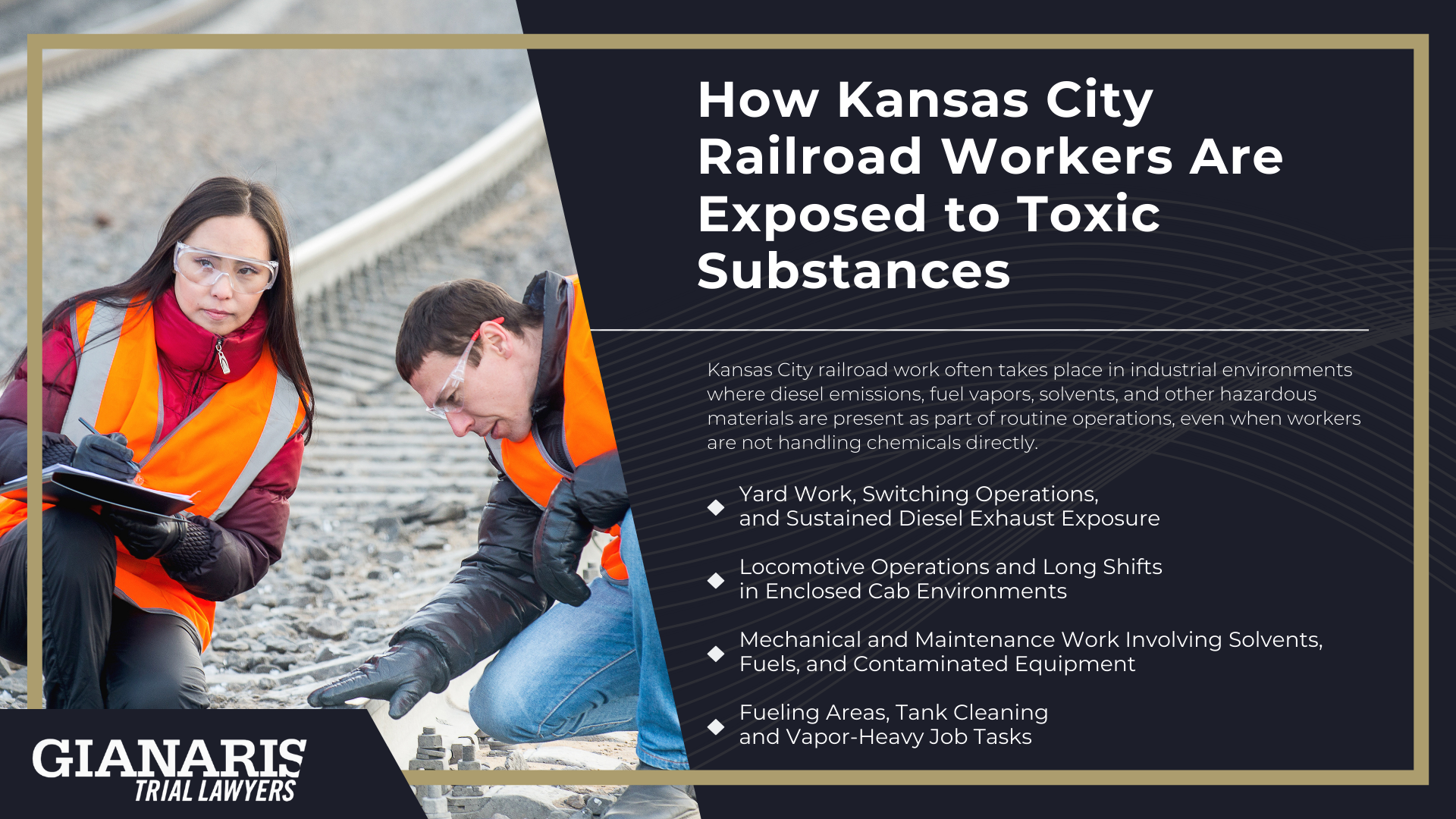

Kansas City railroad work often takes place in industrial environments where diesel emissions, fuel vapors, solvents, and other hazardous materials are present as part of routine operations, even when workers are not handling chemicals directly.

Exposure can occur through inhalation of exhaust and airborne particulate matter in yards and terminals, through contact with fuels and degreasers used during maintenance, and through dust and fumes generated by repair and fabrication work.

For many workers, risk is not tied to a single event but to repeated daily contact: cumulative exposure that can build over a career and contribute to long-term cancer risk.

This applies across a wide range of railroad roles, including locomotive engineers operating around idling engines, mechanical employees working around chemical cleaners and diesel equipment, and crews performing repair work where welding fumes and metal particulates can become routine.

It also includes trades such as sheet metal workers, electricians, and other shop-based workers whose tasks involve cutting, grinding, insulation removal, and component repair in enclosed or poorly ventilated settings.

Because these environments often involve multiple overlapping exposures, claims typically require careful review of job duties, worksite conditions, and the substances present over time when evaluating whether exposed and injured workers developed cancer linked to railroad employment.

Yard Work, Switching Operations, and Sustained Diesel Exhaust Exposure

Yard work and switching operations are often central to railroad cancer claims because they place workers in close proximity to idling engines, heavy equipment, and constant locomotive movement, creating repeated exposure to diesel exhaust over long periods.

The International Agency for Research on Cancer (IARC) classifies diesel engine exhaust as carcinogenic to humans (Group 1) based on sufficient evidence that it causes lung cancer, with additional evidence supporting an association with bladder cancer.

In the railroad industry, these exposures frequently occur in the same areas where diesel-powered equipment runs continuously (yards, terminals, and switching zones) where workers may breathe diesel particulate matter and gases throughout each shift.

In a long-term U.S. railroad worker cohort study published in Environmental Health Perspectives, lung cancer mortality was elevated in jobs associated with trains powered by diesel locomotives, supporting the conclusion that diesel exhaust contributed to lung cancer risk in this population.

Because diesel exhaust is a combustion byproduct of petroleum fuels derived from crude oil, workers in yard environments may also encounter additional fuel-related exposures during refueling, equipment servicing, and spill-related events.

When a railroad fails to reduce preventable exposure, through ventilation practices, engine-idling controls, or protective measures, these cases may be evaluated as potential employer negligence under FELA, particularly when a worker later develops a cancer diagnosis or other serious illness consistent with diesel exposure science.

Common yard and switching exposure conditions that often matter in these claims include:

- Prolonged time near idling locomotives and heavy equipment during switching and staging operations

- Working in areas where exhaust accumulates due to limited airflow, temperature inversions, or enclosed yard layouts

- Repeated exposure over years (“cumulative exposure”) linked to increased lung cancer risk in occupational studies

- Fuel-handling activities in yard environments where diesel vapors and liquid contact may occur during servicing and refueling

- Exposure reconstruction based on job title (yard worker, conductor, switchman, engineer) and years of diesel-era service, consistent with how railroad cohort research evaluates risk

Locomotive Operations and Long Shifts in Enclosed Cab Environments

Locomotive engineers and other train crew members can spend long shifts inside enclosed or semi-enclosed cabs where diesel exhaust enters through doors, windows, ventilation systems, and leakage points, especially when trains idle in yards or operate near other locomotives.

NIOSH exposure assessments aboard diesel locomotives found that crew exposure to diesel particulate matter can vary substantially depending on cab conditions and operational factors such as ventilation and window use.

These findings matter because cab exposure can be repetitive and sustained over a working lifetime, particularly for employees with years of diesel-era service.

IARC classifies diesel engine exhaust as a Group 1 carcinogen, concluding it causes lung cancer and is positively associated with bladder cancer, which is why locomotive work histories are closely reviewed in railroad cancer claims.

Peer-reviewed railroad worker cohort research has also examined diesel-era occupational exposure and reported elevated chronic obstructive pulmonary disease (COPD) and lung cancer risk patterns in diesel-exposed jobs, supporting diesel exhaust as a medically relevant hazard in railroad operations.

Common locomotive cab exposure factors that often matter in these claims include:

- Long shifts in enclosed spaces where exhaust can accumulate during idling, staging, and yard operations

- Cab ventilation and window/door practices that affect diesel particulate levels, as documented in NIOSH crew exposure assessments

- Proximity to exhaust sources, including trailing units and other locomotives operating nearby in terminals and yards

- Cumulative exposure over years of service, which is how occupational research and FELA claims evaluate diesel-related risk

- Overlapping exposures (fuel vapors, solvents, shop contaminants) depending on routes, duties, and time spent in terminals and maintenance areas

Mechanical and Maintenance Work Involving Solvents, Fuels, and Contaminated Equipment

Mechanical and maintenance work is a recurring exposure pathway in railroad cancer cases because it often involves daily contact with fuels, degreasers, cleaning agents, and residue on equipment that has been exposed to exhaust and petroleum products for years.

In these environments, exposure can occur through inhalation of vapors and aerosolized particles during cleaning and repair tasks, and through skin contact when workers handle liquids, rags, parts, or chemical mixtures without full protection.

Public health authorities recognize that benzene can be absorbed through both inhalation and the skin in occupational settings, which is why solvent and fuel work is evaluated carefully when a worker later develops leukemia or other blood-related disease.

This matters because gasoline and other petroleum-derived products contain benzene, and research referenced in environmental exposure literature notes that modern gasoline typically contains roughly 0.5%–2.0% benzene by volume, while diesel contains benzene at much lower concentrations, still relevant when exposures are repeated over many years.

Even when a product is not labeled as “benzene,” exposure can occur through solvent mixtures and cleaning agents, which is consistent with how OSHA regulates benzene in industrial settings and why its standard recognizes benzene exposure risks across multiple operations where benzene or benzene-containing materials may be present.

Common mechanical and maintenance exposure scenarios include:

- Using degreasers and cleaning solvents during locomotive and railcar repair, creating inhalation and skin contact risks consistent with NIOSH and ATSDR exposure descriptions.

- Handling fuel system components and working around refueling and transfer activities where diesel fuel contains trace benzene and fuel vapors may accumulate in enclosed work areas.

- Cleaning equipment coated with petroleum residue, grime, and exhaust-related contamination that can become airborne during scraping, sanding, grinding, or compressed-air cleaning.

- Repeated skin contact with liquid fuels and solvent mixtures, which ATSDR recognizes as an important pathway for benzene absorption in occupational settings.

- Maintenance tasks performed in shops or enclosed spaces where ventilation is limited and chemical vapors can accumulate across long shifts.

- Spill response and cleanup involving fuels and solvent-based products, which can create short-term high-intensity exposure events layered on top of long-term routine exposure.

Fueling Areas, Tank Cleaning and Vapor-Heavy Job Tasks

Fueling areas and vapor-heavy tasks are important in railroad cancer cases because they can involve concentrated exposure to fuel vapors and liquid petroleum products during routine operations.

OSHA’s benzene standard specifically recognizes that workers can be exposed during the storage, transportation, distribution, or sale of benzene or liquid mixtures containing benzene, and it addresses exposure issues tied to loading and unloading operations where vapors are present.

Public health agencies also recognize that benzene can be absorbed by inhalation and skin contact, which means fueling and cleanup tasks can create both respiratory exposure and dermal absorption risk.

These exposures are often evaluated as cumulative career exposures, but spill events, confined-space work, and tank cleaning can create short-term high-intensity exposure episodes layered on top of routine fuel handling.

Common fueling and vapor-heavy exposure scenarios include:

- Refueling operations and fuel transfer tasks where gasoline or fuel mixtures can release vapors in enclosed or poorly ventilated areas

- Tank cleaning and confined-space work involving equipment or containers that held fuel or benzene-containing mixtures, where vapors may remain trapped or re-release during cleaning

- Handling fuel-soaked rags, hoses, and components that can create dermal exposure as well as continued vapor off-gassing

- Spill response and cleanup involving liquid fuels or solvent mixtures that can lead to direct skin contact and concentrated vapor exposure

- Working near intact fuel storage and transport systems where leaks, venting, or degraded seals allow intermittent vapor release over time

- Uncontrolled vapor conditions during loading/unloading in bulk fueling or distribution operations, which OSHA recognizes as an exposure scenario addressed through compliance and monitoring requirements

Why Toxic Exposure Can Occur Even Without Direct Chemical Handling

Railroad workers do not need to handle chemicals directly to experience meaningful toxic exposure, because many hazardous substances are present in the air, on equipment surfaces, and in the surrounding work environment.

Diesel exhaust is generated constantly in yards, terminals, and along active tracks, and workers may inhale exhaust from idling locomotives and nearby equipment even when their primary duties are operational rather than mechanical.

In repair shops and terminals, solvents, degreasers, fuels, and other industrial products can produce vapors that spread beyond the immediate work area, particularly in enclosed spaces or where ventilation is limited.

Toxic residues can also collect on locomotive exteriors, railcars, tools, and work surfaces, creating dermal exposure pathways when workers handle parts, connect hoses, climb ladders, or perform routine inspections.

Creosote-treated railroad ties and ballast dust can release contaminated particles during track work, maintenance, or disturbance of old materials, even when a worker is not mixing or applying chemicals.

In older equipment and facilities, asbestos-containing components may release airborne fibers during routine repairs, retrofits, or disturbance of insulation materials, which can expose nearby workers not performing the work themselves.

For many railroad employees, the risk comes from cumulative exposure over years, where small daily exposures add up across multiple sources rather than one identifiable event.

This is why railroad cancer claims often focus on jobsite conditions and work environment hazards: what was present in the air and on equipment, not only what a worker personally handled.