Railroad welding happens on open track, in shops, and inside locomotives or cars—settings where the welding arc can vaporize metals from the base metal, filler, coatings, and plating material, creating fine particulate and gas mixtures that are easy to inhale.

The International Agency for Research on Cancer classifies welding fumes as carcinogenic to humans (Group 1), with sufficient evidence for lung cancer, and notes that millions of workers worldwide encounter these exposures; ultraviolet radiation from welding also adds cancer risk for the eye and skin.

In rail settings, stainless steel work and certain hardfacing/repair jobs can generate hexavalent chromium (Cr VI), while many processes emit manganese (a neurotoxic metal tied to long-term neurological effects) and a mix of other metals and gases that can reach harmful levels, especially during welding in confined spaces.

OSHA emphasizes that welding produces hazardous fumes and gases and that employers must use effective controls (engineering ventilation, work practices, and respirators) to protect welders and other workers nearby.

A practical example rail crews know well: when working on galvanized components, zinc can vaporize (its boiling point is far lower than steel’s melting range), producing zinc-oxide fume that can cause metal fume fever without adequate ventilation, an acute but serious workplace safety concern.

In addition, surface coatings or electrical contacts and fasteners may contain cadmium or chromium compounds; OSHA’s cadmium standards specifically flag tasks like cutting, welding, or brazing on cadmium-painted or plated materials as a significant risk requiring exposure monitoring and medical surveillance.

When these tasks occur in cars, tanks, pits, or tunnels, confined space welding can accumulate oxygen-displacing gases (e.g., CO₂, argon) and carbon monoxide, making continuous air testing and ventilation mandatory under OSHA guidance.

Because rail welding often happens during outages or emergency repairs, crews may face irregular schedules and variable environments that complicate exposure control, making planning and supervision central to safety.

Finally, even well-ventilated outdoor jobs can expose bystanders (grinders, fitters, or track laborers working a few feet away) so controls must cover the whole workplace, not just the person holding the stinger.

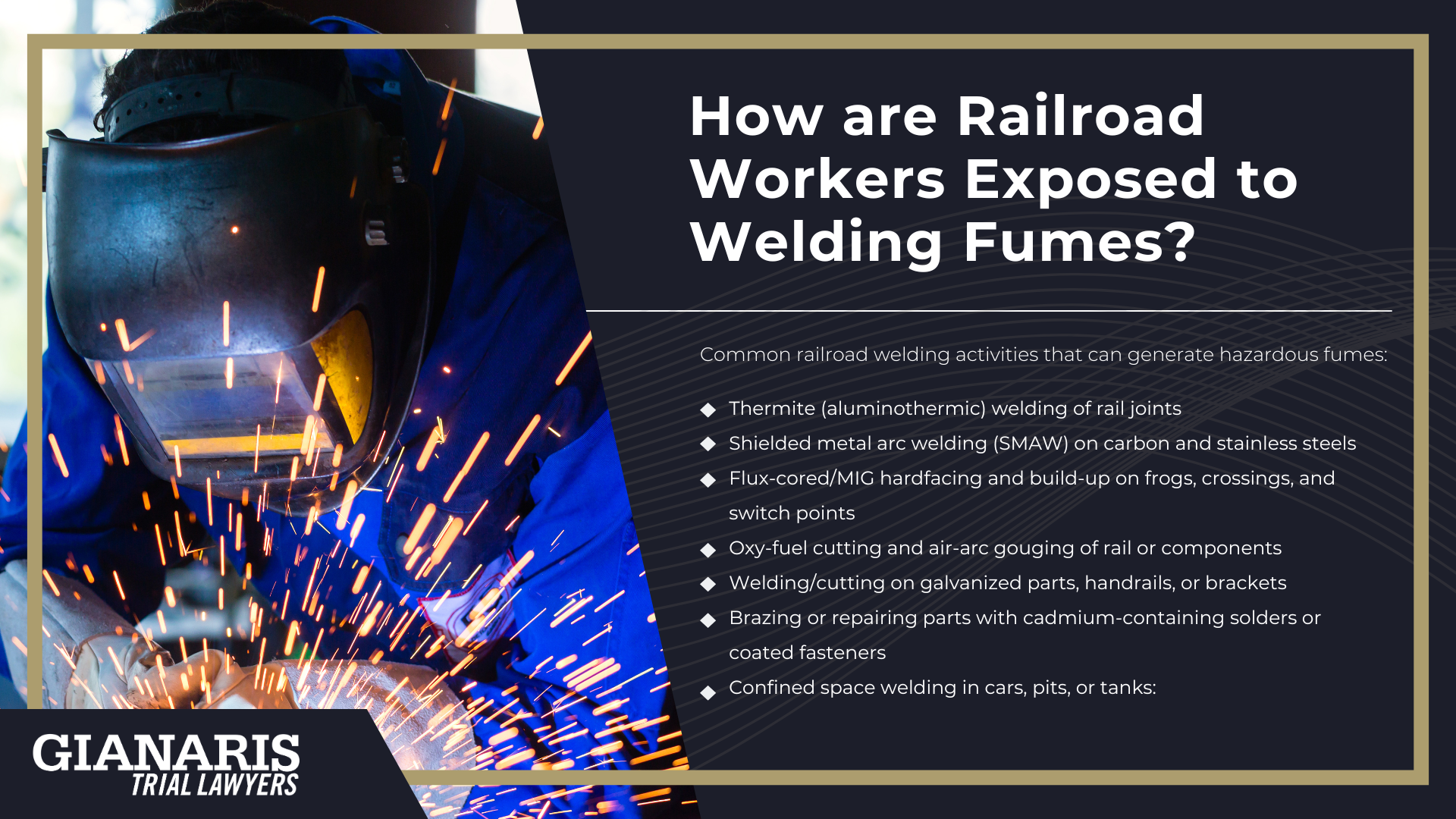

Common railroad welding activities that can generate hazardous fumes:

- Thermite (aluminothermic) welding of rail joints: High-heat reactions and post-weld grinding generate metal fumes and fine particulates.

- Shielded metal arc welding (SMAW) on carbon and stainless steels: Electrodes and alloys can emit iron, manganese, and hexavalent chromium (stainless), plus ozone/NOx from the arc.

- Flux-cored/MIG hardfacing and build-up on frogs, crossings, and switch points: Prolonged arcs on alloy consumables increase metal fume intensity.

- Oxy-fuel cutting and air-arc gouging of rail or components: Volatilizes coatings and releases metal fumes from the base metal and any plating material.

- Welding/cutting on galvanized parts, handrails, or brackets: Zinc fumes can trigger metal fume fever; ventilation and respirators are critical.

- Brazing or repairing parts with cadmium-containing solders or coated fasteners: OSHA treats these as high-hazard tasks requiring monitoring and medical surveillance.

- Confined space welding in cars, pits, or tanks: Oxygen displacement and fume buildup demand atmospheric testing, local exhaust, and rescue readiness.

Railroad welders face mixed-metal fume exposures from processes, consumables, and coatings.

Authoritative agencies (IARC, NIOSH, OSHA) agree that these exposures warrant rigorous hazard assessment and layered controls (local exhaust, process substitution, ventilation plans for confined spaces, respiratory protection, and medical surveillance) to keep exposures below harmful levels and protect both welders and nearby coworkers.

Health Risks Linked to Railroad Welding Operations

The health and safety of railroad workers who perform welding operations has been the subject of numerous occupational health studies, many of which confirm that welding is a high-risk activity with both acute effects and chronic effects.

When an electric arc is struck, the intense heat vaporizes metals from the mild steel or nickel stainless steel being welded, as well as from electrodes and surface coatings, producing fine particles and toxic gases that can be inhaled deeply into the lungs.

These potential exposures depend on the welding process, the metal type, and environmental conditions such as confined space or ventilation quality.

Short-term or acute exposures can trigger irritation of the eyes, nose, and throat, while long-term exposures have been associated with progressive lung function decline and serious respiratory illness.

Welders also face increased susceptibility to lung infection due to compromised airway defenses, along with risks of chronic inflammation and fibrosis.

Over time, many workers develop chronic respiratory conditions, including chronic obstructive pulmonary disease (COPD), which limits breathing capacity and quality of life.

Health effects linked to railroad welding fumes include:

- Acute effects: Eye irritation, throat and nasal inflammation, headaches, dizziness, nausea, and metal fume fever (flu-like illness from inhaling zinc oxide and other fume particles).

- Lung infections: Increased incidence of pneumonia and bronchitis among welders due to impaired lung defenses.

- Reduced lung function: Progressive decline in forced vital capacity (FVC) and forced expiratory volume (FEV1) documented in long-term welding cohorts.

- Chronic obstructive pulmonary disease (COPD): Strongly associated with long-term welding fume exposure.

- Pulmonary fibrosis: Permanent scarring of lung tissue leading to chronic breathing difficulties.

- Occupational asthma: Triggered by exposure to nickel, chromium, and isocyanates in welding fumes.

- Neurological effects: Cognitive impairment, tremors, and manganese-induced parkinsonism from long-term manganese exposure.

- Cancers linked to welding fumes:

- Lung cancer: Welding fumes are classified carcinogenic to humans (Group 1); sufficient evidence that welding fumes cause lung cancer.

- Kidney cancer: IARC notes positive associations between welding fume exposure and kidney cancer.

- Ocular melanoma: Ultraviolet radiation from welding is Group 1 carcinogenic and can cause ocular melanoma.

- Laryngeal cancer: OSHA guidance flags prolonged welding-fume exposure as linked to cancers including larynx.

- Urinary tract cancer: OSHA also cites increased risk of urinary tract cancers with long-term welding fume exposure.