Steel plants are large industrial facilities where raw materials are transformed into the structural metal that underpins modern society.

Steel production typically begins with either coal based steel in blast furnaces or recycling scrap metal in electric arc furnaces, with each method carrying distinct environmental and health implications.

Traditional blast furnaces rely on iron ore and coke, generating massive amounts of air pollution as byproducts of smelting, while electric arc furnaces melt recycled steel using electricity, representing one of the cleaner technologies in the sector.

Both types of facilities are operated by major steel companies and employ complex systems of heavy machinery to refine, shape, and finish steel products.

Coal based steel plants, also referred to as integrated steelworks, often stretch across vast areas with separate units for coking, sintering, smelting, and rolling.

In contrast, mini-mills that use electric arc furnaces are generally smaller, more flexible, and less polluting, though they still present occupational hazards for workers.

Steel plants also have a significant impact on indoor air quality for employees and surrounding communities, as dust, gases, and particulates often escape during production.

The Environmental Protection Agency (EPA) has identified industrial facilities like steel and coke plants as major contributors to regional and global emissions, from greenhouse gases to toxic pollutants.

While technological advances are pushing toward cleaner technologies, the industry remains one of the largest sources of localized environmental and health risks.

The major processes inside a steel plant involve multiple stages of heating, chemical reduction, and shaping:

- Coke production: converting coal into coke for use in blast furnaces.

- Sintering: agglomerating fine iron ore particles into larger masses suitable for smelting.

- Blast furnaces: reducing iron ore into molten iron using coke and limestone.

- Basic oxygen furnaces: refining molten iron into steel by injecting oxygen to reduce carbon content.

- Electric arc furnaces: melting scrap metal and sometimes direct reduced iron (DRI) using electricity.

- Casting and rolling: shaping molten steel into slabs, billets, or finished products like beams, sheets, and wires.

- Finishing operations: applying coatings, heat treatments, and other processes to prepare steel for industrial use.

Steel plants thus represent both economic engines and major sources of environmental stress.

While modern designs emphasize cleaner technologies, millions of workers and community members remain exposed to pollution risks created by traditional production methods.

How are People Exposed to Steel Industry Pollution?

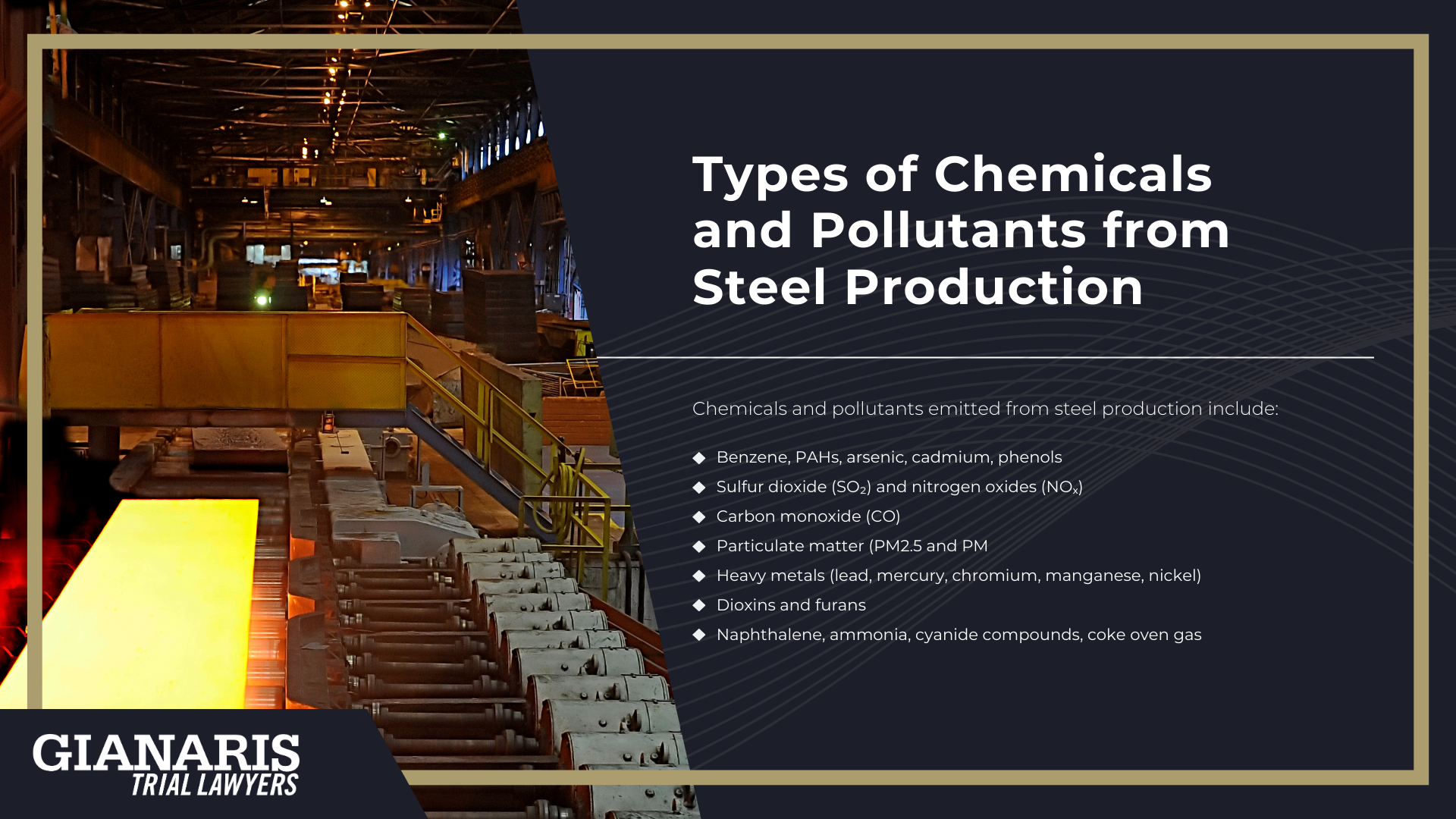

Steel mills, whether they use coal-based steelmaking with blast furnaces and coke ovens, or electric arc furnaces powered by scrap, are significant sources of airborne and environmental pollutants.

Inside these industrial facilities, workers are exposed directly to gases, dusts, and fumes from smelting, coking, welding, and refining processes, despite standards set by the Occupational Safety and Health Administration (OSHA).

Meanwhile, communities living near such heavy industry can inhale pollutants emitted like sulfur dioxide (SO₂), nitrogen oxides (NOₓ), carbon monoxide, and silica dust, which degrade indoor air quality and contribute to serious respiratory conditions.

Asbestos exposure is another major exposure concern related to the steelmaking process.

Under the Clean Air Act, the Environmental Protection Agency (EPA) has long required that pollution from steel plants must be significantly reduced through technological upgrades and enforcement of air quality management standards.

These rules apply across production modes (from conventional coal-based steelmaking to newer, theoretically safer methods such as hydrogen-ready steelmaking) but health advocates argue that implementation often lags behind responsible development.

When equipment failures or large-scale releases occur, hazardous emissions (especially fine particulates and volatile air toxics) can drift miles downwind, exposing residents to elevated pollutant levels even inside their homes.

Over time, repeated exposures are linked to chronic health problems such as asthma, cardiovascular disease, and other respiratory diseases, as supported by public health research.

In short, whether it’s a worker inside the plant or a family living next door, exposure occurs through the air, contaminated soils, dust intrusion, and breakdown of historic protections in practice.