For much of the 20th century, the railroad industry relied heavily on asbestos containing materials for their durability, fire resistance, and insulating properties.

These materials were used throughout steam trains, diesel locomotives, and passenger cars, as well as in the facilities where railroad equipment was built and maintained.

As a result, thousands of railroad workers experienced regular and prolonged occupational exposure to asbestos on the job.

This exposure often occurred without adequate protective gear or safety protocols, and many railroad companies failed to warn workers about the health risks tied to asbestos inhalation.

Asbestos was considered a practical solution to manage heat and prevent fires in high-friction or high-temperature environments—two common characteristics of railroad operations.

However, what many workers did not know is that these same asbestos products could break down and release fine fibers into the air, where they were easily inhaled or ingested.

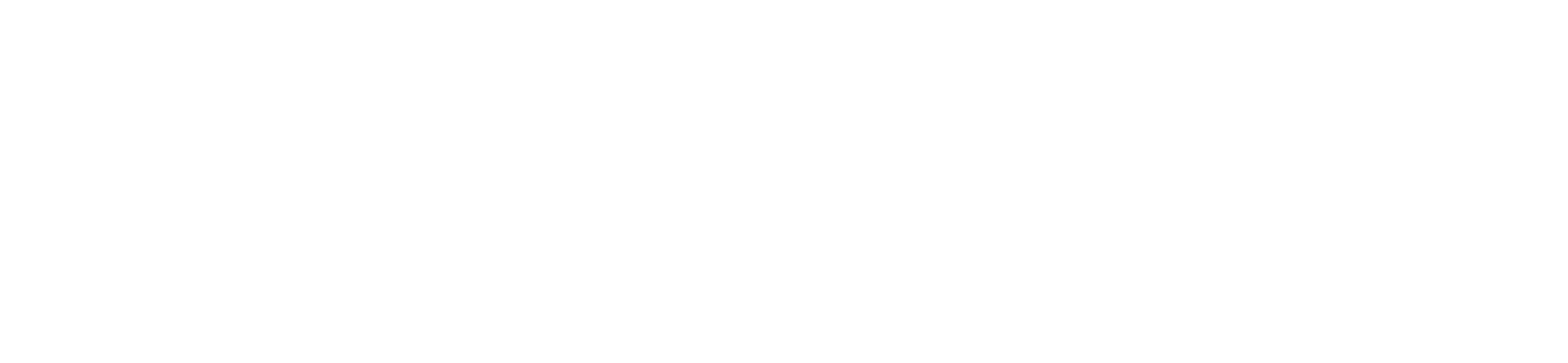

Over time, these exposures have led to an increased risk of serious health issues, including mesothelioma, lung cancer, and asbestosis—diseases that often develop decades after the initial contact.

Even today’s railroad workers can encounter lingering sources of asbestos, especially during restoration or demolition projects involving older equipment or infrastructure.

Many of these materials, although outdated, still remain in older rail yards, repair shops, and retired rolling stock.

Some of the most common sources of asbestos exposure in the railroad industry include:

- Asbestos Insulation: Used extensively on boilers, steam pipes, and engine components in steam locomotives to retain heat and improve efficiency.

- Brake Pads and Linings: Asbestos was a primary material in train brake pads and clutches due to its durability and resistance to heat.

- Gaskets and Seals: Widely used in locomotive engines and railcar systems to prevent leaks under high-pressure conditions.

- Asbestos Rope: Utilized by track workers to repair rail pull-aparts and in various insulation applications.

- Asbestos Cement: Used in railcars to enhance fireproofing and structural integrity.

- Floor Tiles and Adhesives: Found in passenger cars and maintenance buildings, contributing to exposure during installation and removal.

- Protective Clothing: Gloves and aprons made with asbestos fibers were worn by workers to protect against heat, inadvertently exposing them to asbestos.

- Asbestos Heat Shields: Installed in cabooses and passenger car heating systems to manage high temperatures.

- Electrical Panels and Wiring Insulation: Asbestos was used for its insulating properties in various electrical components.

- Ceiling Tiles and Wallboard: Incorporated into the construction of railcars and facilities, leading to exposure during maintenance.

In many cases, workers handled or disturbed these materials daily, creating dust clouds that filled confined spaces without proper ventilation.

Those most at risk included railroad machinists, pipefitters, boilermakers, brakemen, and anyone involved in the repair, renovation, or demolition of rail equipment.

The failure of railroad companies to warn workers or remove these materials safely has left a devastating legacy of disease among both retired and former railroad workers—a reality that continues to affect lives today.

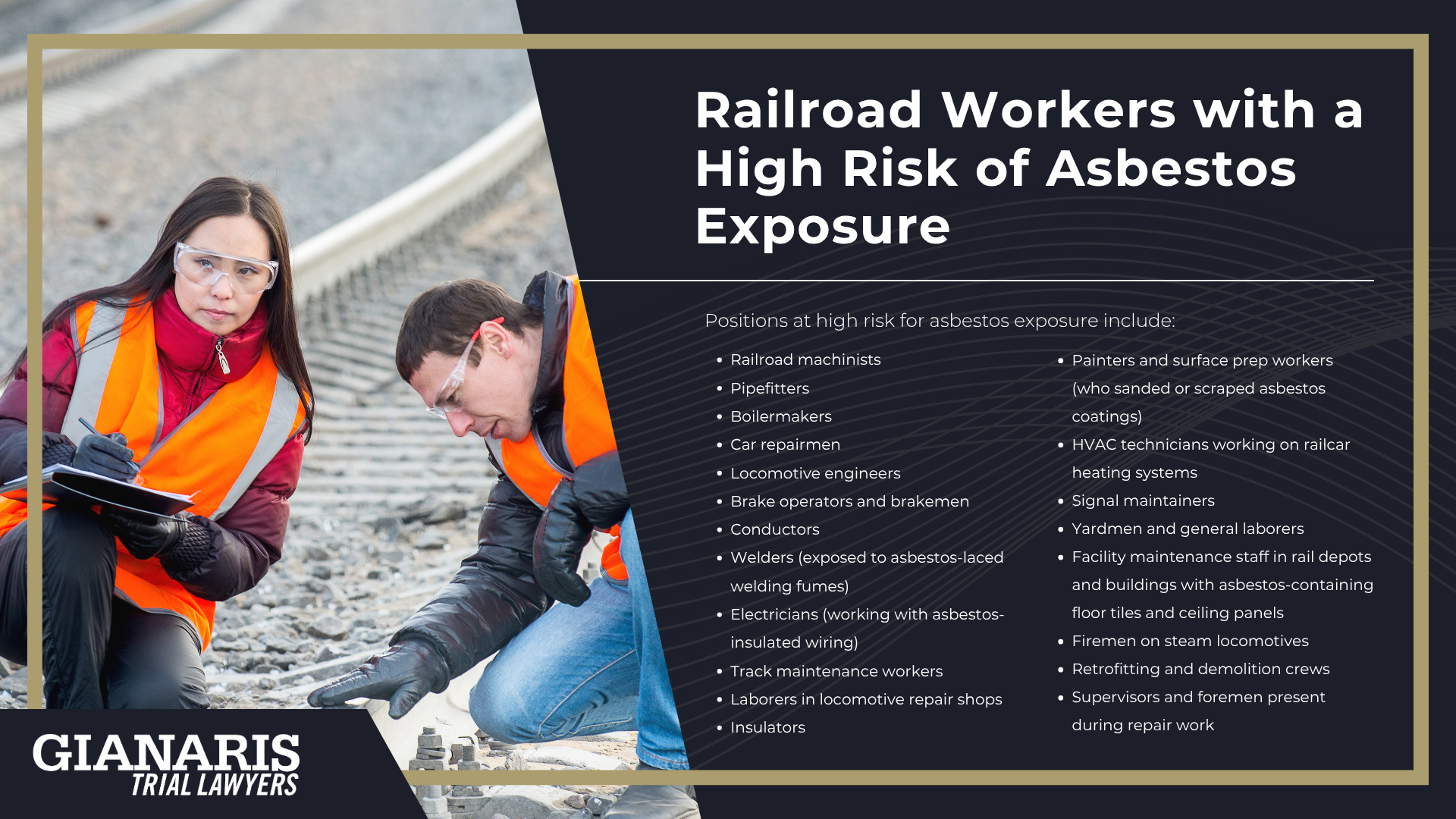

Railroad Workers with a High Risk of Asbestos Exposure

Certain railroad jobs placed workers at particular risk of asbestos-related illness due to frequent contact with materials that contained asbestos.

Many railroad workers encountered asbestos while performing maintenance, repairs, or construction on locomotives, train cars, and infrastructure—often in enclosed spaces with poor ventilation and no protective equipment.

While trades like machinists and pipefitters faced the most direct workplace exposure, other workers were also exposed indirectly through disturbed materials or welding fumes that carried asbestos fibers.

Any railroad employee who worked near insulation, gaskets, brake systems, or asbestos-lined compartments may have been at risk.

Positions at high risk for asbestos exposure include:

- Railroad machinists

- Pipefitters

- Boilermakers

- Car repairmen

- Locomotive engineers

- Brake operators and brakemen

- Conductors

- Welders (exposed to asbestos-laced welding fumes)

- Electricians (working with asbestos-insulated wiring)

- Track maintenance workers

- Laborers in locomotive repair shops

- Insulators

- Painters and surface prep workers (who sanded or scraped asbestos coatings)

- HVAC technicians working on railcar heating systems

- Signal maintainers

- Yardmen and general laborers

- Facility maintenance staff in rail depots and buildings with asbestos-containing floor tiles and ceiling panels

- Firemen on steam locomotives

- Retrofitting and demolition crews

- Supervisors and foremen present during repair work

Each of these roles involved workplace exposure either directly through handling asbestos materials or indirectly by being in contaminated environments where fibers became airborne.