Chemical exposure has long been a hidden danger in the railroad industry, affecting workers across every department from maintenance and repair to locomotive operation and track inspection.

Many of these exposures occur in rail yards, repair shops, or during transportation duties, where workers are surrounded by toxic fumes, dangerous substances, and contaminated surfaces.

Diesel exhaust exposure is one of the most prevalent hazards, especially for those working around diesel engines for extended periods.

These fumes contain fine particulates and chemicals that can penetrate deep into the lungs and bloodstream, leading to respiratory diseases and certain cancers. Benzene exposure is also common due to its presence in diesel fuel, degreasers, and chemical solvents used in maintenance operations.

In older locomotives and facilities, asbestos insulation around steam engines and pipes can release deadly fibers into the air, which workers unknowingly inhale during routine tasks.

Workers may experience really significant exposure over years, often without proper protective equipment or hazard warnings.

These chemical hazards are not limited to a single job type.

They’re embedded throughout the entire work environment, from engine compartments to trackside maintenance zones.

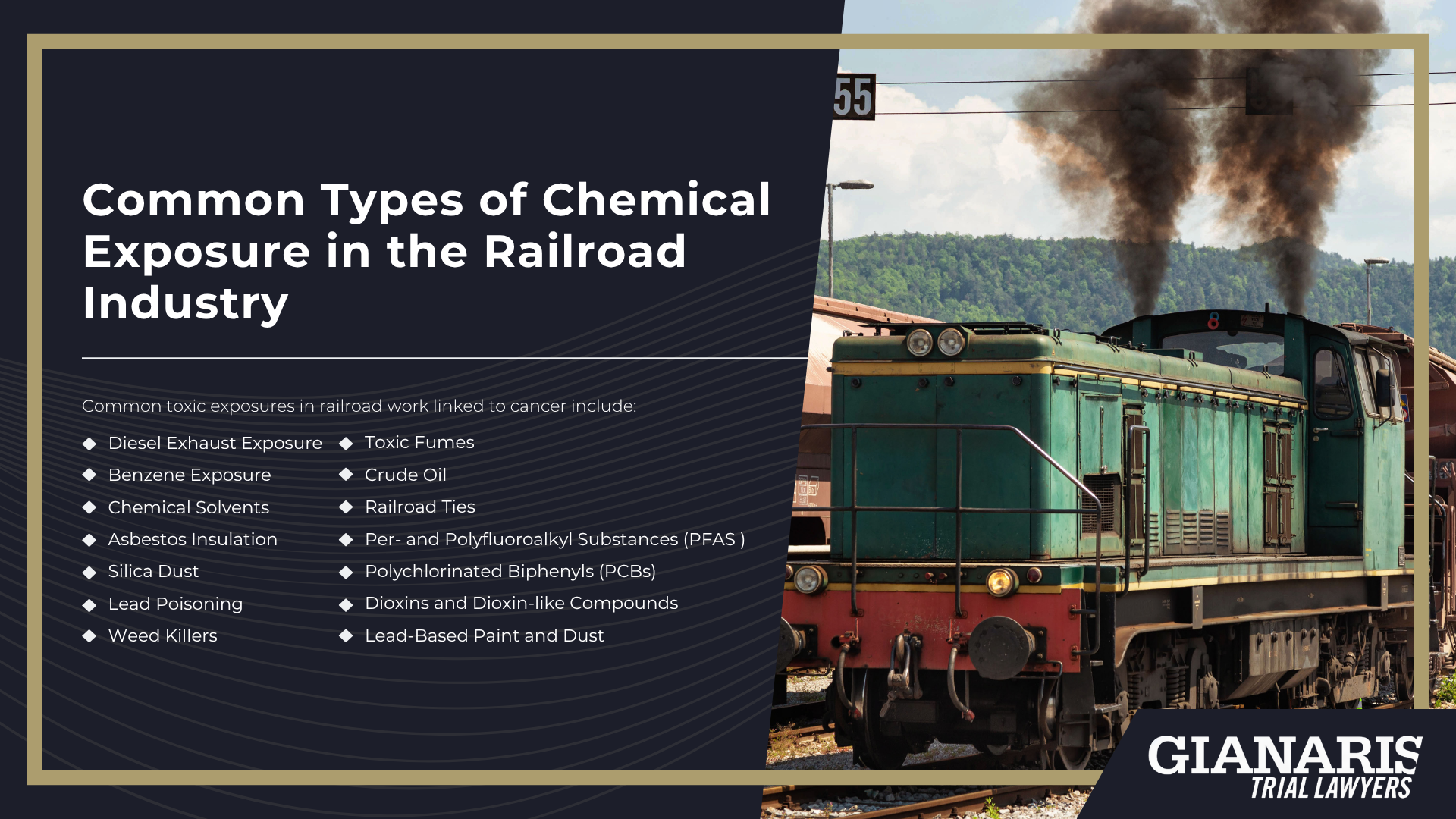

Common types of chemical exposure in the railroad industry include:

- Diesel Exhaust Exposure: Occurs near idling diesel engines in locomotives, especially in enclosed areas like roundhouses or repair shops; linked to lung damage and cancer.

- Benzene Exposure: Found in fuels, degreasers, and industrial solvents; occurs during equipment cleaning, fueling, or chemical storage tasks.

- Chemical Solvents: Used in degreasing, paint removal, and part cleaning; exposure can happen through skin contact or inhalation in maintenance areas.

- Asbestos Insulation: Present in steam engines, brake linings, and old facilities; exposure occurs during repair work or demolition of older equipment.

- Silica Dust: Generated during track repair, cutting, or ballast handling; inhalation causes lung scarring and silicosis.

- Lead Poisoning: Found in old paint and electrical components; exposure through sanding, scraping, or handling contaminated tools.

- Weed Killers: Used to maintain vegetation control along tracks and yards; exposure occurs during spraying or handling containers.

- Toxic Fumes: Released from heated chemicals, welding operations, or chemical spills; often inhaled in poorly ventilated work zones.

- Crude Oil: Transported by rail and present during loading/unloading; leaks or spills lead to inhalation or skin contact risks.

- Railroad Ties: Treated with creosote, a toxic wood preservative; exposure happens through direct contact or inhalation of vapors.

- Per- and Polyfluoroalkyl Substances (PFAS): These synthetic chemicals, often termed “forever chemicals,” are used in firefighting foams, lubricants, hydraulic fluids, and various maintenance products within the rail industry. PFAS are persistent in the environment and have been linked to health issues such as cancer and hormonal disruptions.

- Polychlorinated Biphenyls (PCBs): Despite being banned in the U.S. in 1979, PCBs may still be present in older electrical equipment like transformers and capacitors used in rail facilities. Exposure can occur during maintenance or demolition activities, posing risks such as cancer and immune system effects.

- Dioxins and Dioxin-like Compounds: These toxic substances can be byproducts of industrial processes and may be present in areas where chlorinated organic chemicals were used. Exposure can lead to serious health effects, including cancer and reproductive issues.

- Lead-Based Paint and Dust: Older rail infrastructure may contain lead-based paints. Disturbance during renovation or maintenance can release lead dust, leading to potential lead poisoning, which affects multiple body systems.

Many railroad workers remain unaware of how frequent and harmful these exposures can be.

For example, something as routine as working near old railroad ties or performing welding tasks can result in daily contact with dangerous chemicals.

The cumulative impact of such exposure often leads to chronic health conditions years later, long after employment has ended.

In some cases, symptoms of exposure (such as fatigue, coughing, or skin irritation) are misattributed to aging or unrelated health issues.

Without formal training or hazard warnings, workers may not realize the severity of the risks until serious illnesses, such as cancer or organ damage, have already developed.

The railroad industry has historically underreported and underregulated chemical safety, especially in areas with limited ventilation or outdated infrastructure.

Locomotive cabs, machine shops, and repair pits often trap toxic fumes, compounding the exposure for workers clocking long shifts.

The danger isn’t limited to those handling chemicals directly; secondhand exposure can occur from contaminated tools, clothing, or shared air.

Diesel fumes and solvents, in particular, permeate the work environment and remain airborne for extended periods.

Inadequate protective gear, lack of respirators, and poor cleanup protocols further increase the risk of long-term damage.

Addressing chemical exposure in this industry requires not only better equipment and safety standards but also widespread awareness of how and where these exposures happen.

How Chemical Exposure Happens on the Job: Routes, Tasks, and Risk Factors

Chemical exposure in the railroad industry doesn’t just happen during large spills or accidents.

It occurs gradually through everyday job duties, often without immediate symptoms.

Affected workers may unknowingly encounter toxic materials through routine maintenance, repairs, and inspections.

Whether through direct contact, airborne fumes, or contaminated surfaces, these exposures are frequently underreported and underestimated.

The most common routes of exposure include inhalation of fumes and dust, skin contact with corrosive substances, and even accidental ingestion via hand-to-mouth contact after handling contaminated tools or surfaces.

Exposure levels can vary from moderate exposure during occasional tasks to really significant exposure in roles involving daily contact with chemicals.

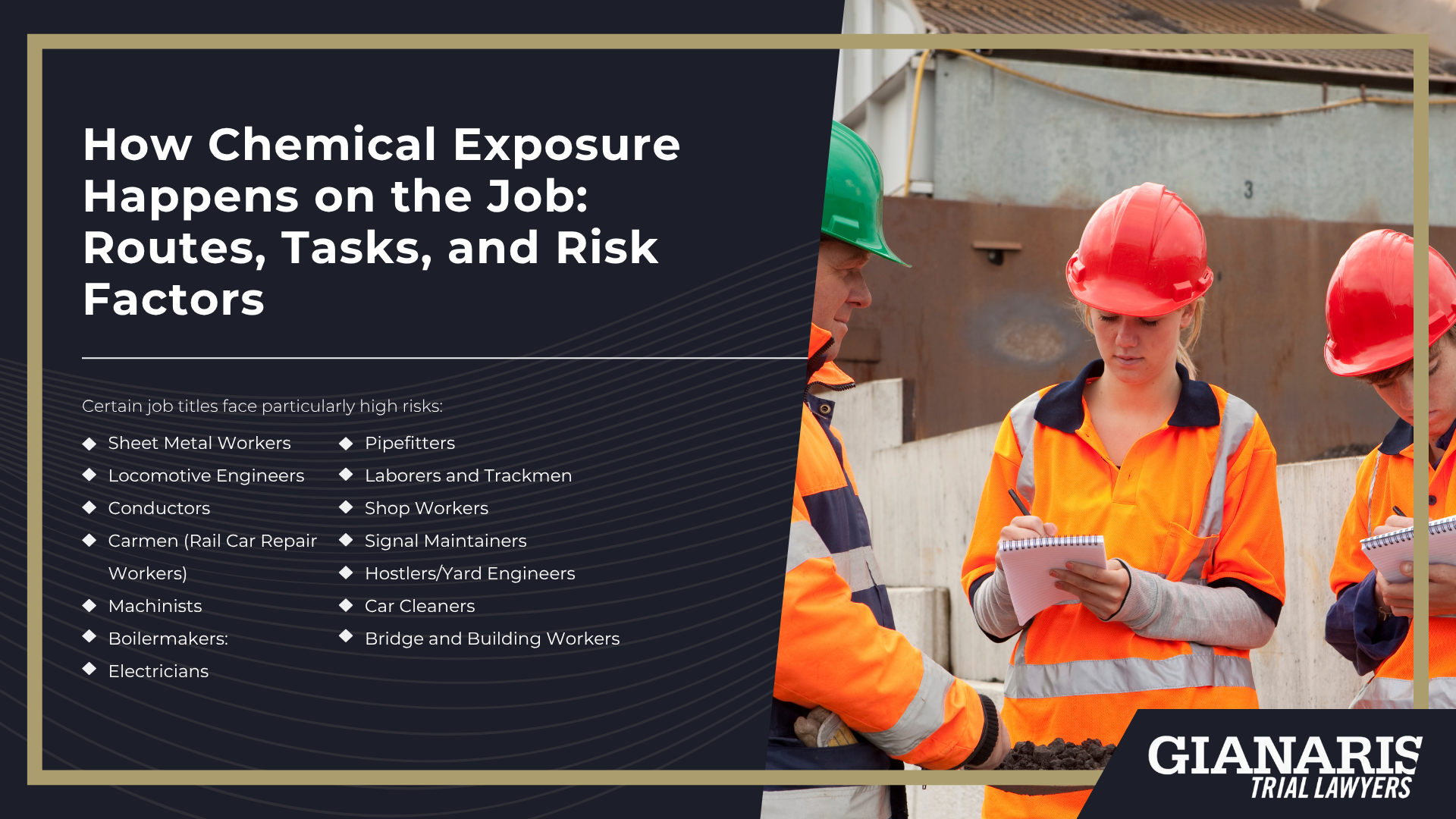

Certain job titles face particularly high risks:

- Sheet Metal Workers: Frequently cut, grind, and weld metal surfaces coated with industrial chemicals, paint, or insulation, releasing fumes and dust into the air.

- Locomotive Engineers: Spend long hours operating diesel engines in confined cabs with limited ventilation, leading to prolonged exposure to diesel fumes and exhaust particulates.

- Conductors: Handle railcars and equipment in yards and along routes where chemical residues, fuel spills, and pesticide applications are common.

- Carmen (Rail Car Repair Workers): Perform inspections and repairs on brake systems, couplers, and car interiors where solvents, lubricants, asbestos insulation, and lead paint may be present.

- Machinists: Work with lathes, grinders, and parts coated in cutting fluids, chemical solvents, or degreasers that produce airborne chemical mists.

- Boilermakers: Weld and repair pressurized tanks or engine components that may be insulated with asbestos or contaminated with residue from hazardous substances.

- Electricians: Encounter PCB-containing transformers, lead wires, and chemical residues during electrical system repairs on locomotives and in facilities.

- Pipefitters: Handle fuel lines and hydraulic systems that may carry crude oil, degreasers, or other corrosive substances.

- Laborers and Trackmen: Engage in creosote-treated railroad tie installation, herbicide spraying, and ballast work that stirs up silica dust and other contaminants.

- Shop Workers: Operate in enclosed environments with welding operations, cleaning stations, and parts washing stations using toxic solvents.

- Signal Maintainers: Often work in remote locations where chemical exposure from herbicides, lubricants, and degraded equipment materials can be overlooked.

- Hostlers/Yard Engineers: Move locomotives in yards with constant exposure to diesel exhaust, oil leaks, and cleaning agents.

- Car Cleaners: Clean railcars with industrial-strength detergents, disinfectants, and degreasers, often in poorly ventilated interiors.

- Bridge and Building Workers: Demolish or maintain structures that may contain lead paint, asbestos insulation, or creosote-treated wood.

Additional factors that increase risk include long shifts in confined spaces, poorly maintained ventilation systems, and inadequate use of personal protective equipment.

Workers may also be exposed during trackside spraying of herbicides, cleaning of fuel tanks, and repairs involving creosote-soaked railroad ties or asbestos-lined components.

Railroad employers are responsible for implementing safety protocols that protect workers from these exposures, yet many fail to provide adequate warnings, respiratory protection, or decontamination resources.

In some cases, affected workers are not told what chemicals they’re handling or the long-term consequences of repeated contact.

Work Environments with the Highest Exposure Risks

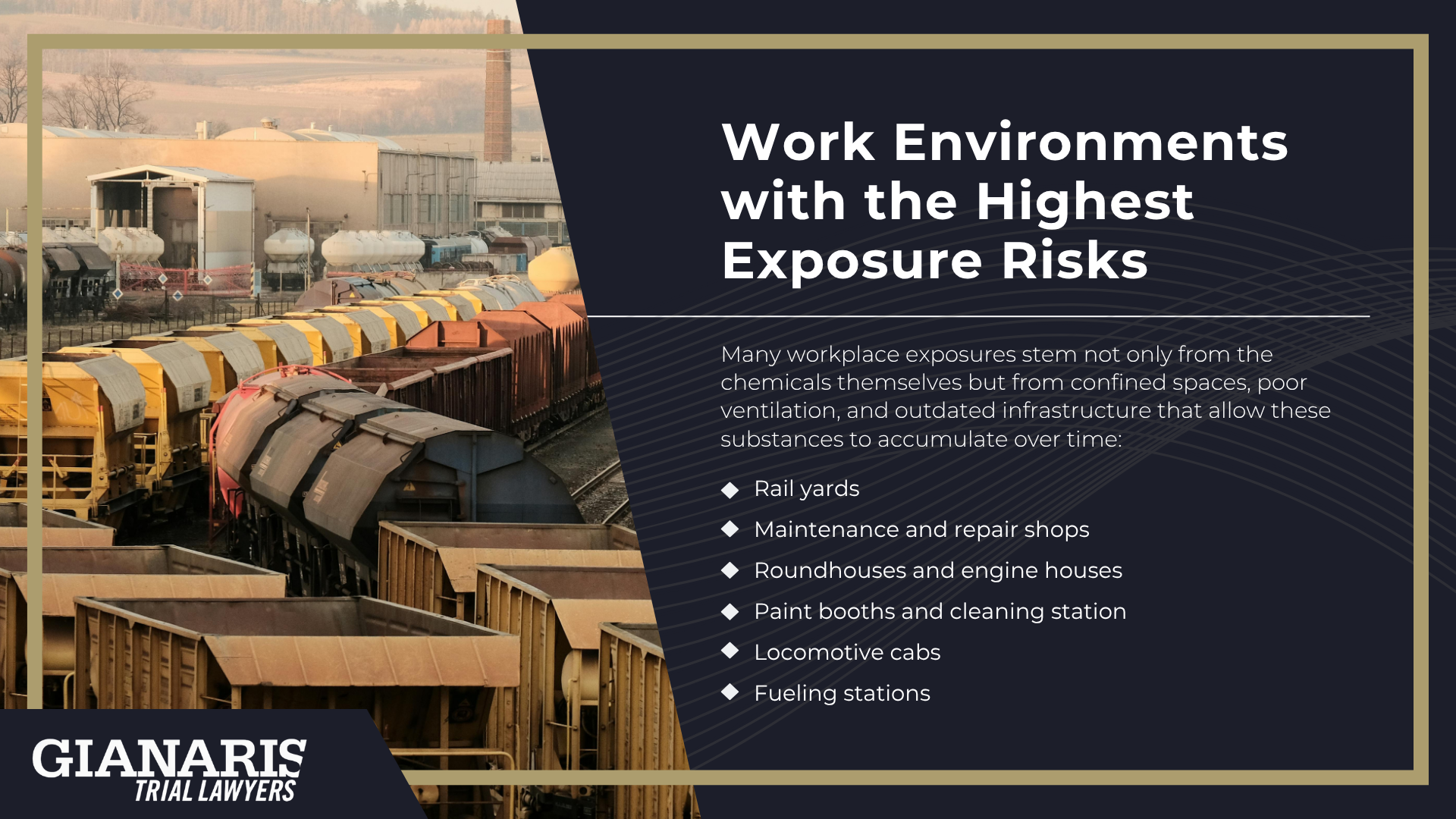

In the railroad industry, certain work environments present far greater chemical hazards than others.

These high-risk areas are where workers are most frequently exposed to toxic fumes, corrosive materials, and contaminated surfaces.

Many workplace exposures stem not only from the chemicals themselves but from confined spaces, poor ventilation, and outdated infrastructure that allow these substances to accumulate over time:

- Rail yards are among the most dangerous locations, with workers exposed to diesel exhaust, chemical spills, crude oil leaks, and herbicides used for vegetation control.

- Maintenance and repair shops often involve welding, grinding, degreasing, and chemical solvent use in enclosed areas, amplifying the risks of inhalation and skin contact.

- Roundhouses and engine houses, where locomotives are parked for servicing, routinely trap diesel fumes and airborne contaminants due to limited airflow.

- Paint booths and cleaning stations also carry a high risk of exposure to solvents, degreasers, and volatile organic compounds.

- Locomotive cabs, especially in older models, can contain lingering diesel exhaust and chemical residues that affect engineers and conductors during long shifts.

- Fueling stations, where diesel, oil, and lubricants are handled without sufficient protective gear, contribute to routine and often unnoticed chemical contact.

Even outdoor settings (like trackside zones where weed killers are applied) pose serious risks when workers aren’t warned about spray schedules or aren’t issued protective equipment.

These environments are all critical points where workplace exposures can accumulate over months or years, often without early symptoms, leaving workers vulnerable to chronic illnesses later in life.